Aqueous Cleaning Optimization

David Gotoff, product manager at Chemetall, explains how each area of an aqueous process must be optimized, including system design and mechanical action, chemistry selection, key performance indicators, soil management, maintenance, rust protection, rust preventive selection, water chemistry, and drying.

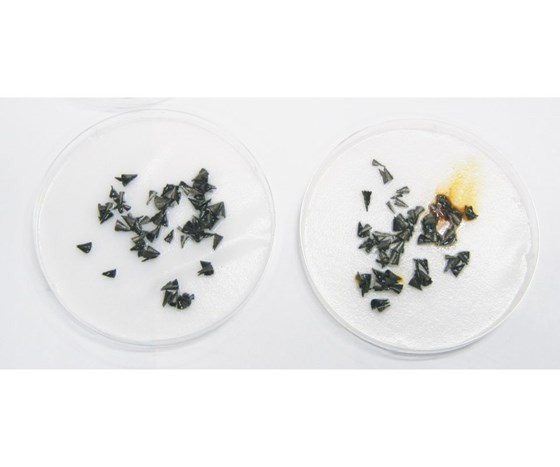

A cast iron chip test will help predict the performance of health and suspect rust inhibitor solutions.

Effective parts cleaning is achievable with the proper chemistry and mechanics. Proper equipment design, coupled with appropriate product selection and process control, assures sustainable and cost-effective performance. And a preventive maintenance program makes the performance consistent over time.

In the article “Optimizing Aqueous Cleaning Requires Proper Design and Maintenance,” David Gotoff, product manager at Chemetall, explains how each area of an aqueous process must be optimized, including system design and mechanical action, chemistry selection, key performance indicators, soil management, maintenance, rust protection, rust preventive selection, water chemistry, and drying. Read the entire article here.

Related Content

-

Kyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

-

PMTS 2023 Product Preview: Parts Cleaning

Learn about some of the latest parts cleaning solutions that will be on display at PMTS 2023.

-

Environmentally Friendly Model 550 Versatile Parts Washer

PMTS 2023: This washer is useful in a variety of applications, including tool rooms, maintenance operations, low production and precision cleaning.

.jpg;maxWidth=300;quality=90)