Commitment to STE(A)M

Collaborative efforts among business, government and education can help to ignite more effective learning opportunities that contribute to the more qualified workforce that manufacturing is striving to develop.

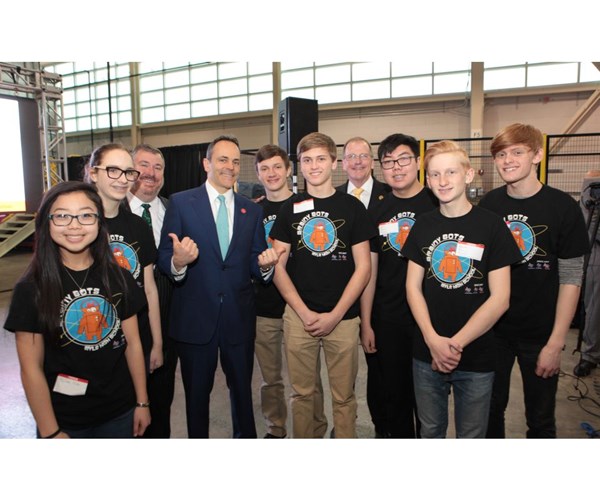

Kentucky Governor Matt Bevin poses with members of the Ryle High School Brainy Bots robotics team.

An important part of the development of qualified manufacturing workers lies in garnering enough interest in the field at the root level. We’ve made strides in the right direction lately, but we still have a long way to go. By offering more programs in schools that give students the opportunity to see how fascinating careers in manufacturing can be, and the chance to see first-hand that it’s not the dirty, dangerous job that many people perceive, we can continue to generate more interest.

In my May column (“A Lesson Often Missed”), I discuss teaching styles—the way subject matter is presented to students—and the impact that these styles have in fostering and maintaining students’ interest. By structuring STEM (science, technology, engineering and math) curriculum to feature hands-on, practical experiences that the students can more easily grasp and apply, learning becomes more fun and effective, thus increasing the desire to continue down the STEM path.

In March, Toyota announced that it is donating its Erlanger, Kentucky-based Quality and Production Engineering lab for development of a STEAM-focused (adding Arts to the equation) education center to serve the Northern Kentucky/Greater Cincinnati region. Collaborating with state and local leaders, the company hopes to offer world-class STEAM education that inspires the next generation to be creative, engaged, highly skilled, tech-savvy, and well prepared problem solvers.

As part of the initiative, Kentucky Governor Matt Bevin announced a $6.8 million Work Ready Skills initiative grant to the county school system to adapt Toyota’s office and engineering lab into a school. Scheduled to open in the fall of 2019, the school will be called the Ignite Institute at Roebling Innovation Center.

Projects such as this collaboration that involve education, industry and government show the importance of growing our workforce to continue to improve manufacturing in the U.S.

Related Content

-

Emerging Leader's Dedication to Education

Instilling confidence throughout a shop floor can do wonders for company morale while increasing productivity.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

-

Recognizing Signs of a Degrading Workplace Culture

Is your machine shop missing key “culture elements?” Here are ways to identify if your organization is heading in the right or wrong direction in terms of establishing a healthy company culture.

.jpg;maxWidth=300;quality=90)