If the machines on your shop floor could talk, what would they say? Would they tell stories of being cared for and maintained to the utmost degree, or would they disclose being abused or neglected? Would the turning center that broke last week explain precisely why an alarm went off causing the machine to be out of commission since then? Would it know how many parts it produced in a day or how many hours/minutes it ran last month? Would the CNC Swiss lathe sitting in the corner alert an operator of a potential tool failure before it happens?

Imagine having all this information at your fingertips. The data collected would be a gold mine to management; it could be used to make more informed decisions on the shop floor as well as optimize processes. Money and time would be saved and return on investment (ROI) would be easy to calculate.

Eric Fogg, co-founder and COO at MachineMetrics, says his company’s monitoring and communication system can make these ideals attainable for a shop by helping discover paths to efficiency. This product is also said to bring transparency to machine tools through machine data collection.

“MachineMetrics can collect any data that is useful to a customer,” he says. “That data can be whether the machine is running, how many parts it has made, and its alarm history, for example. We take all the data, encrypt it and forward it to our cloud service where we perform analytics and create dashboards for our customers to use.”

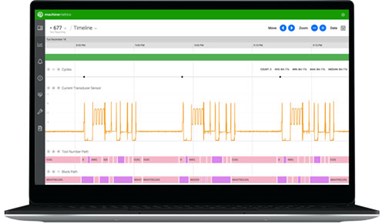

MachineMetrics’ monitoring and communication system can make a shop’s ideals attainable by helping discover paths to efficiency. This product is said to bring transparency to machine tools through machine data collection. (Photo courtesy of MachineMetrics.)

The company uses an edge device that lives in each of its customers’ machines that can remotely update, making the system hands-off and low-maintenance for machine shops.

Although this machine monitoring concept is cloud-based, it sheds light on practical, actionable measures that can be taken to alleviate real-world issues at the ground level. For example, it can help:

1. Make Old Problems Go Away

One shop’s operators found an effective way to communicate with its management through MachineMetrics. These operators “hated” two old machines in their shop that continued to break down, causing a lot of downtime and headaches with fixing them. However, management hoped to hang on to the machines because they had already paid for them. But when MachineMetrics connected its system to the outdated equipment, the problems revealed themselves to management, which showed how much time was being lost in repairs. Two weeks after that, the shop bought two new machines to replace the old ones.

2. Understand Why Crashes Happened

Machine tool crashes often revolve around uncertainty because sometimes an operator will not admit fault. Shop management understands production time is being lost, but might not know the real reason why the machine crashed. “The machine OEM is in a hard place because if it has to repair a spindle under warranty, that’s a big hit to take if it thinks the machine crashed because of someone’s error,” Fogg explains. “With tools like MachineMetrics, you can look back in time and get a very good understanding of why it crashed, reading all the alarms and alerts from the machine and looking at the load of the spindle over time. This gives management power to make more informed decisions.”

In addition, managers can receive an alert on his or her phone or tablet device the moment a crash happens, greatly reducing the reaction time for fixing the problem.

3. Manage Planned Maintenance

With the machine tool OEMs that MachineMetrics has partnered with, the product can manage planned maintenance (PM) within a machine, eliminating the need for a shop to manually track machines’ production hours. The edge device can track hours in production and alert the operator when it’s time for PM.

“OEMs like this capability because operators are doing more PMs, and they are doing them by the book,” Fogg says.

4. Enable Remote Communication

MachineMetrics’ connection to its cloud service enables machine monitoring and remote communication with shops anywhere in the world. These

MachineMetrics is able to collect machine data that tells operators and/or machine OEMs when a machine is running (cycle time), how many parts it has made, alarm history and more.

communication features are especially critical now during the COVID-19 crisis when technician travel is unsafe or not permitted.

An example of how these features worked to the advantage of both the shop and the machine OEM is in a story of a broken lube line. One of MachineMetrics’ OEM partners was receiving repetitive alerts from a customer’s machine that it needed its way oil refilled. The system detected that every other similar machine rarely received this alert. Therefore, the OEM knew there was a leak somewhere. After communicating this to the shop, it saw that the lubrication line running to the subspindle bearing was damaged, and that bearing was running without oil.

“They repaired the lube line and, to my knowledge, there was no failure to the bearing,” Fogg says. “If MachineMetrics was not connected to this machine, the subspindle bearing would have failed and the machine would have been taken out of production for a period of time, maybe a couple weeks. A technician from the OEM would have had to go on site as well.”

Predicting the Future

Catching issues in machines before they become catastrophic failures is the goal at MachineMetrics. “Our overall theme is moving from a reactive to a proactive paradigm,” Fogg explains. “We are rolling out the ability to predict tool failures, which represents a huge area of growth for us.”

The company’s system is understanding tool failure and stopping a machine before it wastes time and money creating scrap parts.

MachineMetrics | 413-531-7490 | machinemetrics.com

Learn More

Moving Toward a Smart Factory with Manufacturing Analytics

MachineMetrics’ real-time data allows companies to make fast, proactive decisions to bring efficiency to their processes. Read more here: gbm.media/machinemet

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreAutomation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

Read MoreZoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

Read MorePrecision Machining Technology Review October 2023

Production Machining’s October 2023 technology showcase includes some of the latest technology from Tungaloy-NTK America Inc., Renishaw, Walter USA, Seco Tools and Haimer USA.

Read MoreRead Next

Data-Driven Manufacturing Helps Shops Stay Competitive

MachineMetrics Inc. provides machine monitoring software that helps manufacturers make decisions based on real-time data, in one case helping a shop to gain almost 20-percent improvement in machine usage in the first year of use.

Read MoreOur Precision Machining Industry Responds

This moment-in-time article describes the challenges multiple precision machine shops faced — and met — to support customers’ and employees’ needs during the COVID-19 pandemic.

Read MoreHow to Collect and Use Machine Data

Manufacturers don’t need to limit the machine monitoring data they collect, but they do need to know how to collect the data and how to use it to drive decisions.

Read More

.jpg;maxWidth=300;quality=90)