Lean Six Sigma Training Benefits Companies, Customers

Companies may face obstacles when implementing Lean Six Sigma practices, but the quality improvement and waste reduction can have long-term benefits in customer satisfaction, work culture and efficiency.

Investing in Lean Six Sigma black belt training for employees is time-consuming and expensive, but many companies have found that the benefits to their own businesses and their customers are worth it.

Lean Six Sigma’s black belt training can be time consuming and expensive. It pulls valuable employees away from their daily commitments. The training is rigorous, and certification is not guaranteed. But companies including 3M, GE, Ford and even Allied Machine & Engineering, a 78-year old family-owned cutting tool manufacturer, continue to invest in the training. Implementing Lean Six Sigma can be intimidating, but businesses committed to educating employees in key roles throughout their organization can see long-term benefits in customer satisfaction, work culture and efficiency.

Lean Six Sigma methods are rooted in process improvement systems like Total Quality Management (TQM) and have evolved over time. Motorola’s Bill Smith coined the term Six Sigma in the early 1980s, which originates from a statistical measure. Its main goal is to consistently produce no more than 3.4 defects per million opportunities (DPMO).

Initially, Six Sigma was used exclusively in parts manufacturing, but over time companies like 3M and GE started using it in other areas too. In the 2000s, companies began combining Six Sigma’s quality improvement methods with the waste reduction methods of lean manufacturing, creating Lean Six Sigma. As defects are reduced, waste is reduced, so the two practices complement each other well. The strategy proved so successful that by 2009, 82% of Fortune 100 businesses had implemented Lean Six Sigma practices.

With such successful businesses using Lean Six Sigma tactics, executive leadership at Allied Machine realized the importance of educating key players to shape a continuous improvement culture and sustain process excellence. Black belt training was the perfect solution.

The company’s executive vice president, Steve Stokey, participated in black belt training alongside employees. “I chose to go through the training to be able to lead the cultural shift at Allied,” he says. “It is vital that I hold the organization accountable to effectively use the tools to continuously improve our business. By learning the nomenclature, understanding the software, and working on a black belt project with my team, I am living the change process with them.”

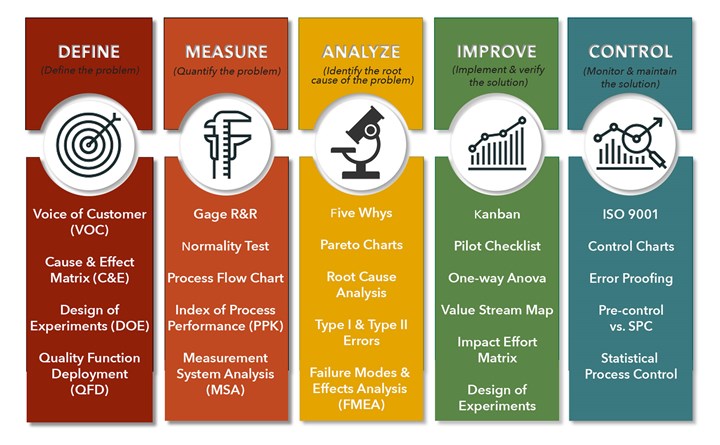

One aspect of black belt training is learning to use the DMAIC methodology for process improvement.

Throughout the training, facilitators instruct candidates in advanced Lean Six Sigma, covering the DMAIC (define, measure, analyze, improve, control) methodology, nomenclature, analysis software, data-driven techniques for process improvement and more. Participants learn and practice higher-level procedures in the final week of classroom instruction.

Once classroom sessions conclude, trainees lead a black belt project that must make a significant financial impact and support strategic initiatives. The project is the proving ground for all the skills covered during classroom sessions and generally takes three to six months to complete.

Trainees submit their project to the certification trainer for review and, if approved, they receive black belt certification. Not all participants achieve this status. “Black belt training not only identifies potential leaders in our workforce, but it also identifies areas for improvement, even in existing leaders too,” notes Ross Randazzo, the director of operational excellence at Allied Machine. Along with processes and products, the training also provides continuous improvement opportunities for an organization’s workforce.

Helping Customers

Organizing black belt training for leadership roles across various departments is no small feat, but in the end, it benefits the most vital component to an organization’s success and longevity—its customers. It systematically defines a roadmap to match the voice of the process with the voice of the people. In other words, it teaches how to listen to customers and align internal quality standards to meet the end user’s needs.

In the 1990s, Ford was struggling with low productivity, environmental issues, and very low customer satisfaction rates. In response, they began a consumer driven Six Sigma focus. Ford poured through surveys and feedback to target the top 25 critical customer concerns for each vehicle line and developed a process improvement strategy to address each. The hard work drastically improved customer satisfaction ratings, according to Quality Digest. By setting standards that mirrored their customers’ expectations and monitoring processes to consistently meet them, Ford demonstrated the value of their customers’ feedback and restored credibility.

Lean Six Sigma certification conveys that an organization is dedicated to producing and delivering the best products and services on time, every time. “Customers receive higher quality goods in a faster time frame with better reaction to problems,” according to classroom facilitator S. Skillman.

Six Sigma can benefit customers in six ways:

- Communication. Customers deserve to be heard and communication is a critical component of Lean Six Sigma. Understanding a customer’s requirements and making them your own is a mantra repeated throughout training. The terminology used in Lean Six Sigma provides a common language for businesses and their customers. It puts an emphasis on gathering the right information from clients in order to shape internal quality standards.

- Trust. End-users also want to trust their suppliers. Lack of transparency, inconsistent compliance, and varying lead times chip away at vendor relationships. By training employees in the data-driven processes, organizations like Allied Machine have documentation that can provide compliance visibility to their customers. Tracking and archiving data through control systems and analysis software allows employees to react quicker to significant variances and reinforces customer trust.

- Quality. “When customers realize a company invests in Lean Six Sigma training and is ISO certified, it gives them confidence,” says John Frazier, a master black belt and manufacturing manager for Allied Machine. “They understand this supplier is going to pursue excellence in everything they offer.” Companies using Lean Six Sigma’s structured, data-driven methods are dedicated to quality and, more importantly, define quality through the eyes of their customers.

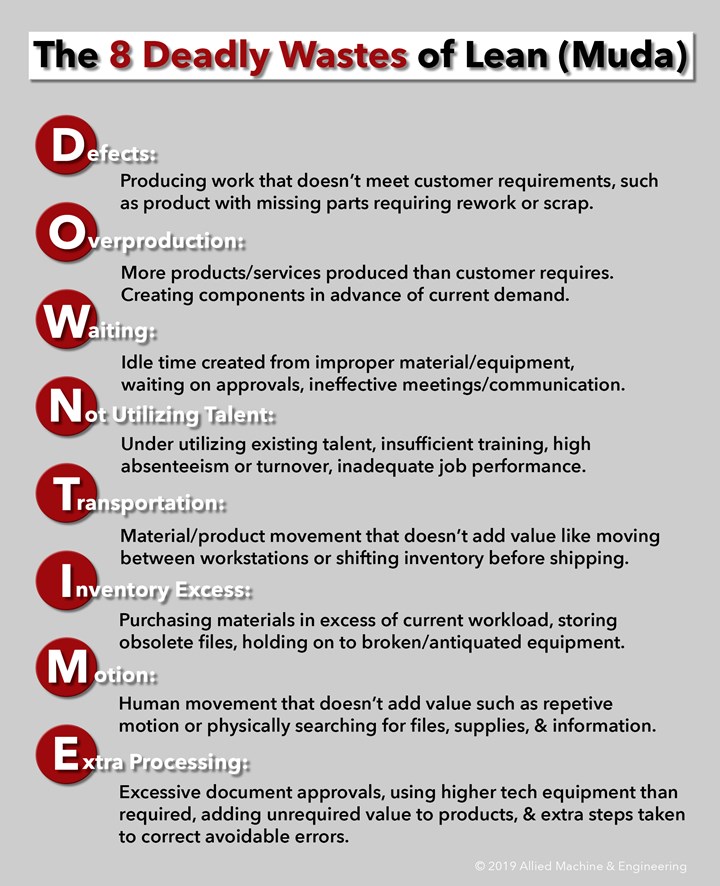

Lean Six Sigma also works to eliminate the eight deadly wastes of manufacturing.

- Innovative Products and Services. Streamlined processes also help bring new products to market faster. Black belts are certified experts in identifying and reducing the eight deadly wastes often found in manufacturing. Whether identifying bottlenecks, removing unnecessary movements, or eliminating creep from project meetings, Lean Six Sigma methodology helps businesses navigate process developments smoothly and deliver innovations to customers quicker.

- Improved Environmental Impact. Customers concerned about the environment can also look to manufacturers practicing Lean Six Sigma. Reducing energy consumption, minimizing material waste and streamlining processes all make positive impacts on the environment. According to the EPA, 3M reduced volatile air emissions by 61% from 2000 to 2005 through Lean process improvements. The EPA has even developed a Lean guide specifically for environmental professionals. Emphasis on reducing specific waste groups helps provide a safer work environment, competitive pricing on products for customers and a healthier community for all.

- Shorter Lead Times. In order to improve reliability, organizations are always looking to improve delivery times. Black belts exercise critical thinking skills and mentor staff to proactively streamline processes so that customers receive orders faster. Employees are encouraged to think how they can make a significant difference, whether by reduced movements in a particular work cell, improving inventory maintenance, or simplifying a system for packaging.

Avoiding Stumbling Blocks

Integrating Lean Six Sigma into a company’s culture is not easy. Time and resources are obstacles for successful deployment. Intangible factors can also stunt integration, including fear of change and lack of leadership buy-in.

Egos can cripple a continuous improvement culture. Jacob Miller is a master black belt and the director of product and process development. He’s been working at Allied Machine for 13 years and understands people struggle with the fear change. “We have to get over ‘this is the way we’ve always done it’ and realize it’s going to make things easier for everyone involved in implementing processes,” he advises.

As for buy-in from management in the organization, if they don’t believe in the power of data-driven decisions and process improvements, they’ll never reap the full benefits of Lean Six Sigma. Ownership and the executive board ultimately set the tone for the company’s culture and are responsible for dedicating resources and removing roadblocks along the way. It’s imperative that leaders define the goals, understand the tools, and create a strategy for top-down deployment.

Investing in Lean Six Sigma black belt training is good for companies, their customers and their people. Worldwide, businesses know what to expect from a company that adheres to this process. “There are plenty of cutting tool manufacturers out there competing to gain the market’s attention,” Mr. Stokey summarizes. “We know our people need to be trained at the Olympic level of waste reduction and quality control if we’re to continue winning their business and their loyalty.”

Related Content

Emerging Leader's Dedication to Education

Instilling confidence throughout a shop floor can do wonders for company morale while increasing productivity.

Read More2023 Emerging Leaders Strengthen Their Staffs, Solve Problems

Superb critical thinking, top-notch leadership skills and a passion for building a strong team are a few of the common traits held by this year’s five Production Machining Emerging Leader award winners.

Read MoreNew Thinking from the New Generation for the New Year

“We have to learn to think in a new way.” –Albert Einstein

Read MoreGift a 3D Printer to an Employee?

Some shops have purchased inexpensive polymer 3D printers for their operations. Does it make sense to take this a step further and give (or loan) a sharp young employee one to experiment with at home? This small investment could pay off for your shop in different ways.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)