Parting Blade Adapter Delivers Precision Cooling

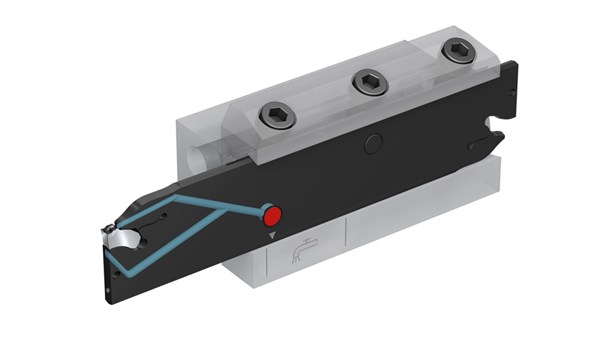

After flowing through the adapter, the coolant is transferred directly through the parting blade to the cutting zone, targeting the exact point of material removal.

This new design provides optimal cooling of both the insert and the parting blade.

Parting blade adapters for machines with BMT/DO-style turrets from Walter USA distinguish themselves in two key ways: The coolant flows through the adapter, and it is transferred directly through the parting blade to the cutting zone. Both of these new features are crucial for ensuring optimal cooling of both the insert and the parting blade, the company says.

An O-ring seal ensures that the coolant is transferred effectively and without loss of pressure. For particular cases, the adapters can also be used with external cooling, either instead of internal cooling or in addition to it. All that is needed is to shut off the coolant nozzle that supplies coolant internally. The systems are designed so the user only needs a single bracket, whether they are installing them in the standard position or overhead. The center height for each individual workpiece can be adjusted as required on the adapter itself within a range of ± 0.5 mm. This allows an exact center position to be achieved for the workpiece that is to be machined, without needing to carry out any extra work.

The precision of the coolant supply means that only short chips are produced and relatively little wear occurs when using these new parting blade adapters. The downtime required to clear large volumes of accumulated chips is a thing of the past, the company says, while at the same time the machine’s productivity increases. The robust holder is designed to allow machining in any position required and eliminates vibration during operation. The adapters work with a coolant pressure of 10 to 80 bar, which means they can be used on virtually any of the machines that are currently available on the market and feature a BMT interface.

Related Content

-

Repeatability and Rigidity Are Key for Quick-Change Swiss Tooling

A rotary wedge clamping system is said to enable this two-piece, modular tooling system for Swiss-types to offer the performance of a solid tool.

-

New Cutting Tool Technology Discovered at Paul Horn Open House

During a tour of the company’s campus in Tubingen, Germany, I and more than 3,000+ others were introduced to a number of new advances the company has made in cutting tool technology particularly as it relates to the medical industry.

-

The Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

.jpg;maxWidth=300;quality=90)