Robot Aids Additive Research

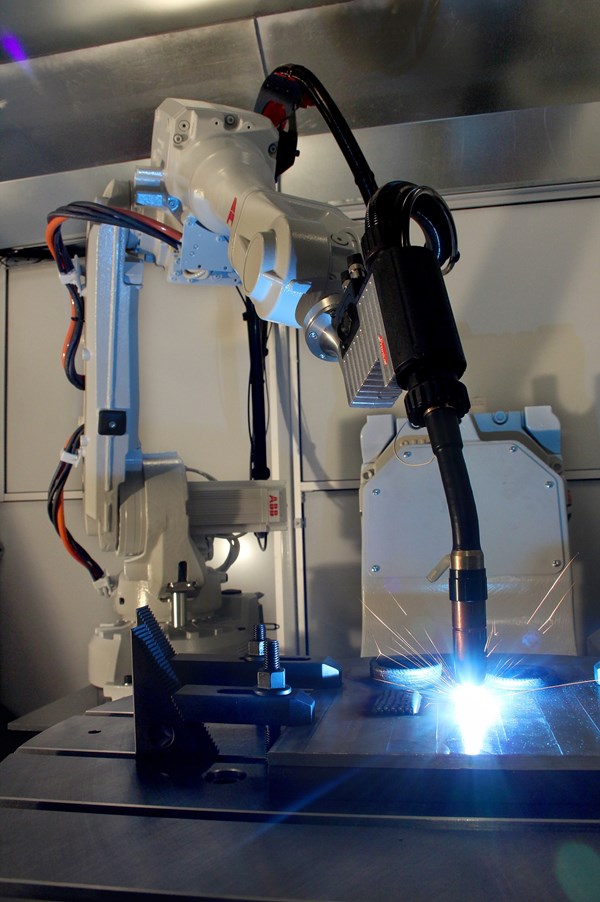

Delcam's ABB robot that's fitted with a cold metal transfer welding head will be used mainly for research in robot programming for metal additive manufacturing.

This six axes robot is being used by Delcam at its research facility to explore cold metal transfer applications in additive manufacturing.

Delcam has added an ABB robot fitted with a Fronius cold metal transfer welding head to the range of manufacturing equipment at its Birmingham, England, site. The new unit will be used mainly for research in robot programming for metal additive manufacturing using the company’s PowerMILL Robot software.

Cold metal transfer welding was initially developed by Fronius to join materials with different properties, in particular for welding aluminium to steel. The process uses high frequency movement of the wire to give a clean, spatter-free material transfer. It provides a stable, reproducible deposition of material that Delcam believes should have great potential in metal additive manufacturing.

The robot arm offers six axes of movement, with an additional two axes, tilt and rotation, provided by the table holding the material. This additional flexibility allows parts to be oriented into the optimum position as they are being built, so enabling complex shapes to be created with less need for extra support structures.

While making it possible to program robots for additive manufacturing, the software can be used for tool-to-part applications, especially for machining large parts, such as composite panels that need to be trimmed, or for part-to-tool applications, such as grinding or polishing.

Related Content

-

Automation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

-

Pursuit of Parts Collector Spearheads New Enterprise

While searching for a small parts accumulator for Swiss-type lathes, this machine shop CEO not only found what he was looking for but also discovered how to become a distributor for the unique product.

-

High-Volume Machine Shop Automates Secondary Ops

An Ohio contract shop added a compact, self-loading CNC lathe to perform unattended secondary ops on a part for a key customer rather than running it on a manually loaded chucker.

.jpg;maxWidth=300;quality=90)