Shorten the Training Curve with Cognitive Mapping, Part 2

We can give someone information, but that does not mean that that person has converted that information into usable knowledge.

Editors Note: This is a multi-part series about properly training your employees. Be sure to also read:

Part 1: The Learning Curve

“Information is not knowledge, let’s not confuse the two.” - Deming

Years ago, I was in charge of a group of technical writers for a manufacturing company, and we were responsible for writing all of the setup and operating procedures for six factories. What I noticed was that my degreed technical writers were writing nonsense as far as many of the workers were concerned. The SOPs met the industry standards, but they did not serve the very people for whom they were intended. The workers needed training material that they could, in fact, read, understand and retain. Since these people generally are not “readers”, but are “lookers” (try to build the Christmas bike from the parts diagram rather than the text instructions), it seemed to me we needed to revise the way we provided information to them.

We can give someone information, but that does not mean that that person has converted that information into usable knowledge. If they do not, we end up with an employee whose lack of knowledge, despite their training and information, is destined to make a bad product, break a machine or injure themself or someone else. Only then do we recognize that our assumption on the level of knowledge that employee had is wrong.

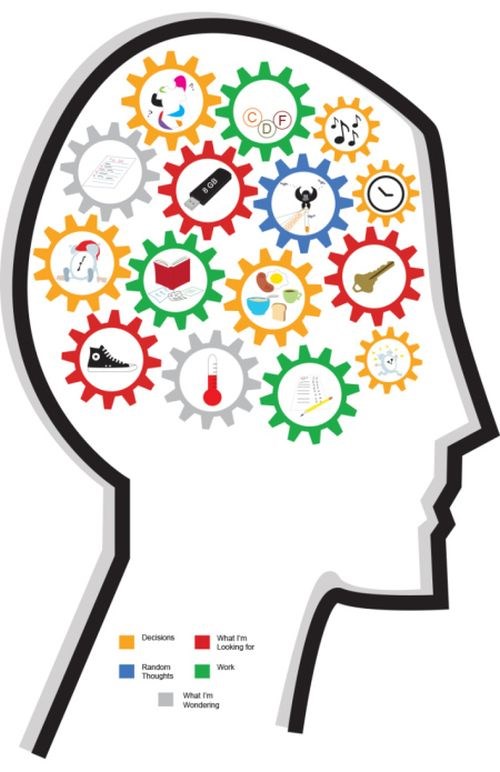

His or her cognitive map was inaccurate or incomplete.

How can we do better?

- We can provide information to employees in a form and format that makes it remarkably easy for them to understand.

- We can reduce the amount of encoding and decoding needed to digest the information provided for the training.

- We need to make it easier for the employee to understand.

If we do these things, the employee can form an accurate cognitive map, not just be confused by complicated and misunderstood instructions.

Our experience has shown that to help employees form accurate cognitive maps, we need to reduce the amount of text and maximize the use of visuals and imagery.

If you go to this page on our website, you can download a PDF that demonstrates how management can provide information in a form and format that the employee can more readily convert to knowledge.

It does not take a technical writer to produce this.

Once produced, and shared with the employee, we know what his cognitive map looks like because our images helped him construct it, without decoding. If a quality problem pops up, we can measure the accuracy of that employees work by comparing what he or she does with the illustrated work instruction.

Our workforce has changed. We need to change our approach to training, and our cognitive mapping technique reduces the learning curve and improves worker accomplishment.

What are your strategies to improve employee competency? How are they working out? Click this link to get further background on the ViewIt Training System.

Originally posted at PMPASpeakingofPrecision.com blog.

Related Content

-

2023 Emerging Leaders Strengthen Their Staffs, Solve Problems

Superb critical thinking, top-notch leadership skills and a passion for building a strong team are a few of the common traits held by this year’s five Production Machining Emerging Leader award winners.

-

New Thinking from the New Generation for the New Year

“We have to learn to think in a new way.” –Albert Einstein

-

Video Tech Brief: CNC Screw Machines a Solution for Overcoming Labor Shortages

CNC screw machines can exceed job shop productivity and enable manufacturers to overcome perpetual employment gaps.

.jpg;maxWidth=300;quality=90)