3 Threading Options for Holemaking

Thorough analysis before selecting and committing to tooling will produce quality holemaking in the most efficient and cost-effective way. Here's a look at three ways to cut threads.

Many challenges and options exist for threading holes. The importance of paying close attention and examining your application’s needs, and then taking the time to get advice from the cutting tool experts is vital for success. In the end, thorough analysis before selecting and committing to your tooling will produce quality holemaking in the most efficient and cost-effective way. The following methods/examples may provide some assistance in determining the best solution for the threading process.

Versatility and Speed on Tap

For many applications, taps may prove to be most effective. Taps have the ability to produce threaded holes with short cycle times, uniform quality and longer tool life.

Shops that perform short and medium run threading applications across a range of materials may do well to consider taps that are both general purpose and high performance. These types of taps can significantly improve thread quality and boost output while reducing production costs, because one high performance, multiple use tap can handle most common materials including carbon steel, steel alloys, stainless steel, aluminum and cast iron. Also, a general purpose tap eliminates the need to stock numerous types of taps in the tool crib.

Look for general purpose, high performance taps that are designed to cut threads to both the common 2B class of fit, as well as the tighter 3B class, eliminating the guesswork of calculating H-limits. For instance, Emuge Corp. offers a tap in this category, said to be the industry’s first general purpose, high performance tap.

If speed is an objective, “full-speed” taps are available that tap two to five times faster than conventional tools. This speed is achieved through unique design characteristics of the taps in areas such as relief, back taper, length of thread and flute geometry. In addition, these full-speed taps also feature the best hard surface coatings available and where appropriate, coolant-through technology is also employed.

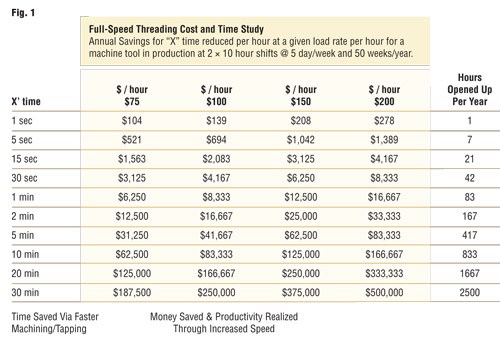

When all the features are combined, success can be impressive to say the least. The taps allow exceptionally fast tapping at record-level speeds on modern CNC equipment. Increased speed produces tremendous production savings and efficiency because speed reduces cycle time while improving thread quality. If tapping time is reduced by 10 minutes per hour at a machine rate of $150, annual savings of $125,000 can be achieved and capacity can be increased by 833 machine hours.”

For example, one of these full-speed taps, running at 75 sfm tapping a 3/8-16 inch blind hole in stainless steel, would likely cut machining time in half, demonstrating the savings that can be realized with full-speed tapping as shown in Figure 1.

A Choice for Thread Mills

Depending on the application, another useful alternative to thread cutting is through thread milling. These tools are designed for high cutting speeds and feeds and produce threads with excellent form, finish and dimensional accuracy. Precision and accuracy are ensured by exact thread depth and position control.

Thread milling is very efficient in large part because of the accuracy and speed of modern CNC machine tools.

Other thread milling advantages include, but are not limited to, easy machining of difficult materials, elimination of the possibilities and consequences of tap breakage, and the production of small controllable chips. When you combine thread milling with the latest CNC technology and smart controllers, you can realize outstanding flexibility, process control, tool life and part quality.

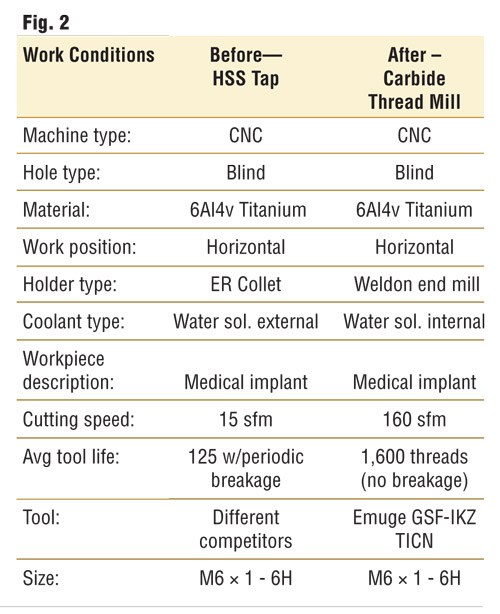

Figure 2 shows an application example where the choice of thread mills proved beneficial.

Thrilling Solution

Another highly productive way to both make and thread holes is by using thrillers—cutting tools that actually reduce the number of holemaking operations by combining hole drilling, threading and chamfering in one operation. This is accomplished via a solid carbide cutting tool that includes a twist drill point, a thread milling element for threading, a chamfering element, and a straight cylindrical shank with flat for clamping.

Thread making with thrillers, when used in a modern CNC machine with helical interpolation ability, offers unparalleled speed, flexibility, precision cutting, tool life and value compared with conventional thread cutting methods. Several of the many benefits thrillers offer include the ability to produce high quality threads with excellent fit, form and finish, high cutting speeds and feeds, plus one tool is used for both left- and right-hand threads and for through and blind holes. In addition, thrillers eliminate the need for self-reversing tapping attachments and no reversal of the spindle is required.

Perhaps the biggest difference is how thrillers significantly improve productivity because of the number of cutting operations they eliminate. This is made possible with multi-functional tool designs that combine

operations.

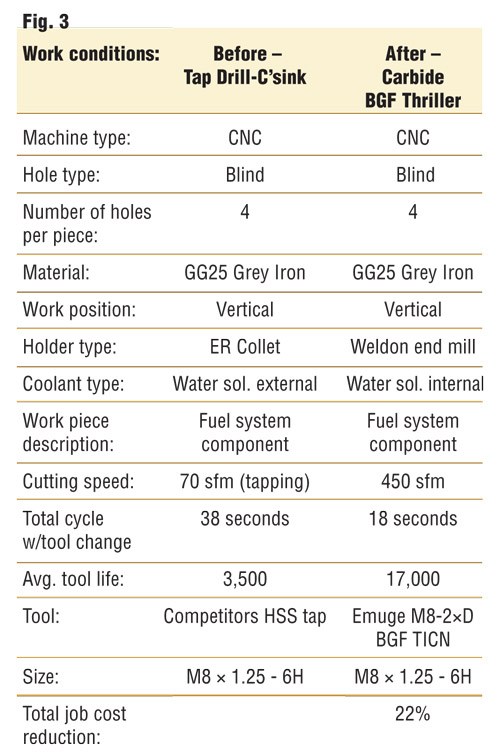

The thriller example, shown in Figure 3, resulted in a 22 percent job cost reduction.

With so many tools in the market for threading applications, it is imperative to consult with cutting experts to choose the best tool for your application. Doing so will improve productivity and quality, while reducing cost in your holemaking operation. It pays to carefully analyze the threading application at hand before any chips are made.

Related Content

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreRepeatability and Rigidity Are Key for Quick-Change Swiss Tooling

A rotary wedge clamping system is said to enable this two-piece, modular tooling system for Swiss-types to offer the performance of a solid tool.

Read MoreNew Cutting Tool Technology Discovered at Paul Horn Open House

During a tour of the company’s campus in Tubingen, Germany, I and more than 3,000+ others were introduced to a number of new advances the company has made in cutting tool technology particularly as it relates to the medical industry.

Read MoreRead Next

Tips for Improved Holemaking

A few drill types dominate holemaking, a machining process made up of sub-areas that are evolving along with changing drill capabilities.

Read MoreWhen Thread Milling Makes Sense

Threading a workpiece is a fundamental metalworking process that every manufacturing engineer takes for granted.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)