Thin rings such as this one are candidates for a photo-activated adhesive workholding process. The process eliminates part distortion that can might happen when conventional, mechanical clamping devices are used.

For some turning applications, chuck jaws or other conventional workholding devices for CNC lathes can cause a part to distort as clamping force is applied. This can be the case for large, thin rings such as the one shown on the left. Those workholding elements can also prevent full access to a part, which might necessitate reclamping for an additional operation.

Blue Photon offers an alternate workholding method for these types of situations that uses adhesive cured by ultraviolet (UV) light to secure a part for turning. It can also be used for other processes such as milling, grinding, electrical discharge machining and 3D printing/additive manufacturing.

After cleaning grippers with isopropyl alcohol, adhesive is deposited on each one.

The primary components for the company’s photoactivated adhesive system are a UV light source with a light guide, BlueGrip adhesive and UV light-transmitting grippers that serve as lenses through which the UV light passes to cure the adhesive and bond a part to a fixturing element.

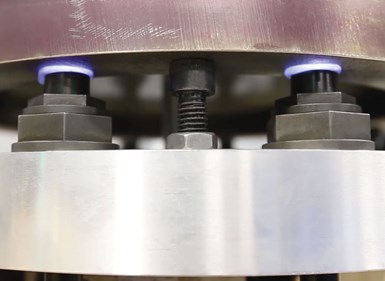

The threaded grippers install in the top of a fixture plate and require a through-hole to enable the UV light to pass up and through the gripper to cure the adhesive. For most turning applications, this would be done at a workstation and the fixture plate with bonded part would then be installed on the lathe.

Hard stops, such as Allen bolts are used to provide the proper adhesive gap between grippers and part.

To do this, the top of each gripper and the areas of the part to be gripped are cleaned with isopropyl alcohol. Adhesive is deposited on the top of each gripper so that the entire gripper face is covered and the gap between the face and underside of the part is filled. The gaps (thus, the thickness of the adhesive) can range from 0.020 to 0.120 inch, depending on part flatness. The part rests on hard stops installed in the fixture plate that are slightly taller than the gripper tops to achieve the proper gap.

To cure the adhesive, the UV light source’s light guide is inserted into the backside of each gripper and the source is activated. It typically takes 60 to 90 seconds for the UV light to cure the adhesive, bonding the gripper to the part. Once curing is complete for all grippers, the fixturing element with the part can be installed in the machine and machining can be performed.

With the fixture removed from the machine, a wrench is used to back off each gripper and break the bond with the part.

Once machining is completed, a wrench is used to back off each threaded gripper, shearing the adhesive bond with the part. The residual adhesive can then be peeled off the part and grippers after applying steam, or a hot water soak or spray.

The number of required grippers is based on the size of the part and its geometry, the company says. Axial holding force depends on gripper size and can range from 250 to 800 pounds. Grippers are made from hardened, corrosion-resistant stainless steel and have a black oxide finish. The adhesive is compatible with most water- and oil-based coolants and cutting fluids. It is said to be able to hold a variety of ferrous and nonferrous metals as well as plastics, ceramics and composite materials.

Related Content

The Value of Auto Adjust Magazine Bar Feeders

This bar feeder is designed to offer the flexibility to enable CNC turning centers to perform short-run work that would otherwise require frequent setups over a range of barstock diameters.

Read MoreWhen to Use a Diaphragm Chuck

The accuracy and repeatability of these chucks make them well suited for a number of workholding applications, including turning and grinding.

Read MorePMTS 2023 Product Preview: Workholding

Learn about some of the latest workholding solutions that will be on display at PMTS 2023.

Read MoreAutomating Complete Workholding Changeovers for Turning

Robotic loading of all workholding elements is perhaps the next logical step to create fully automated yet flexible machining cells for CNC turning centers even when batch sizes are small.

Read MoreRead Next

Hitting the Target with Creative Workholding

While growth has been steady in its Swiss operations, this archery equipment supplier’s most drastic improvements have come at the hands of the workholding systems on its VMCs.

Read MoreSubspindle Workholding Options

The advent of subspindle turning operations has impacted throughput for many shops. Understanding workholding options available for backworking can help a shop make better decisions when specifying how to hold parts for op. 20.

Read MoreMagnetic Workholding for Production Parts

The use of magnets for workholding has grown well beyond its traditional role for flat plate materials. Control of magnetic flux is now precise enough to securely hold a much wider array of workpiece configurations.

Read More

.jpg;maxWidth=300;quality=90)