Offset-Style Swiss Toolholders Clear Up Clearance Issues

It’s no secret a Swiss-type machine’s tooling zone is a busy place where space utilization is critical.

Share

It’s no secret a Swiss-type machine’s tooling zone is a busy place where space utilization is critical. Now, as Swiss parts have become even smaller, clearance remains a common issue, potentially leading to a road block or crash.

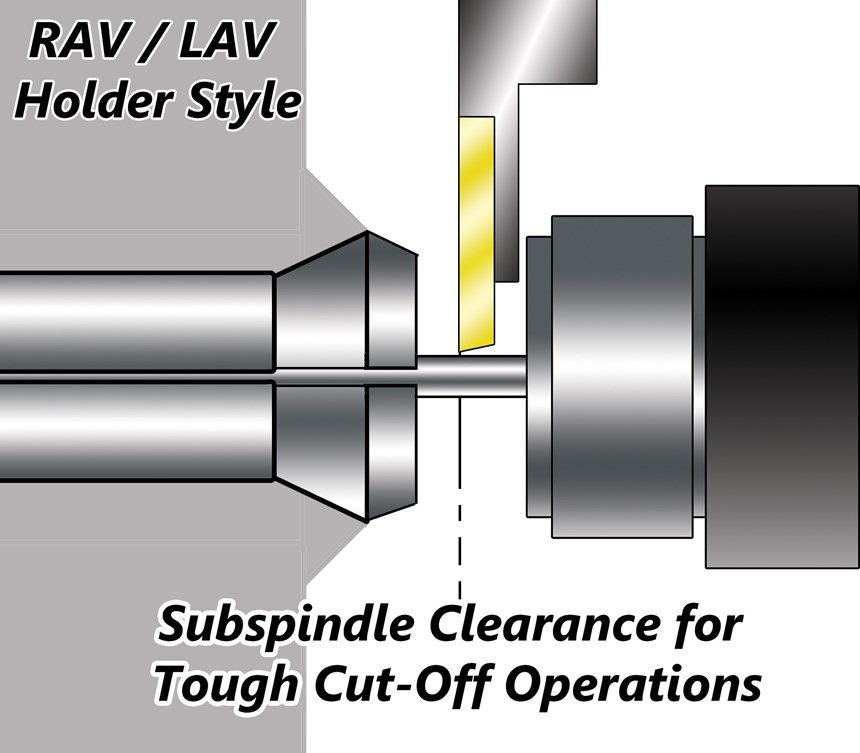

GenSwiss now offers the Utilis offset-style Swiss toolholders to address clearance concerns for the subspindle during partoff and for extended nose guide bushings. By design, these offset holders enable the pickoff/subspindle to get close enough to accurately cut off short, small-diameter parts without barstock deflection for better throughput and higher quality. These toolholders are particularly suitable for medical thread whirling applications using clearing extended-nose guide bushings. In addition, for larger barstock operations where a left-hand holder is used in a right-hand machine (or right-hand holders in a left-hand machine), they can be used in place of quick change insert systems. The operator can change inserts without removing the toolholders.

Read more about how these toolholders can help your shop save time by eliminating clearance issues for uninterrupted production.

Related Content

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

-

Rego-Fix Through-Coolant System for Swiss-Type Machines

PMTS 2023: The reCool RCR/ERM system provides all the benefits of reCool technology to Swiss-type machines while also enabling the use of emulsion or pure oil coolants.

.png;maxWidth=300;quality=90)