Technology Hits the Road

As a strategy to assist in its tradeshow follow-up efforts, this company has put a demonstration vehicle on the road to bring its technology to prospective customers.

For this editor, this spring has been a season of trade shows. I've traveled to WESTEC, PMTS and EASTEC. Of course, with many exhibitors displaying at more than one of these shows, I've enjoyed the benefit of being able to re-visit technologies that caught my eye, ask additional questions and delve further into topics than many other show attendees. Not everyone has the opportunity to go to as many shows as I do, and with the fast-paced atmosphere on the show floor, often attendees walk away wishing they had more time with certain exhibitors to see their products up close and in action.

One company has taken these concerns to heart and has developed a demonstration vehicle that allows it to take the show—or at least its portion of it—on the road. Haimer USA is bringing its line of shrink-fit toolholders, tool balancing and other technology to its prospective customers via its new technology demonstration vehicle.

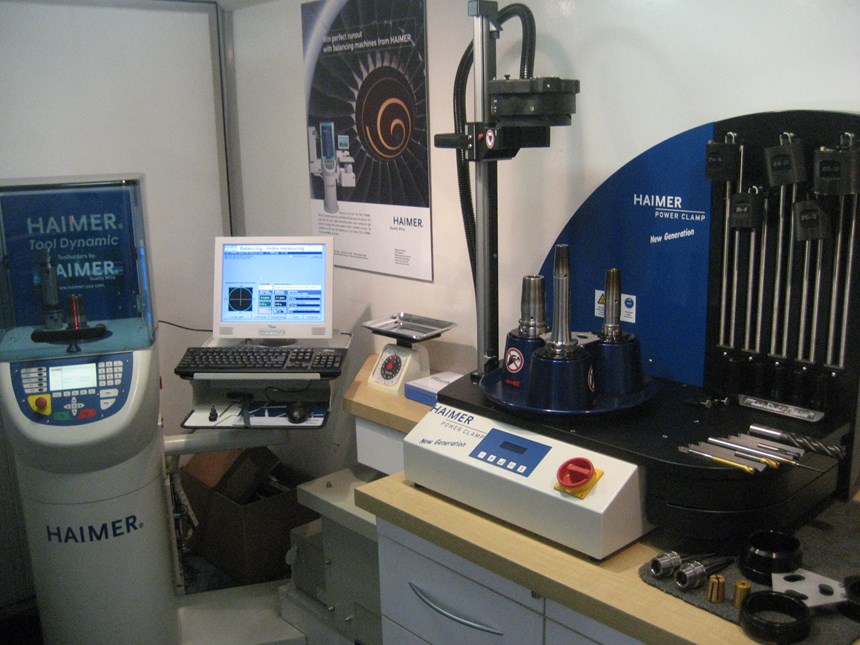

Mounted on the chassis of a GMC Top Kick C4500 diesel is a 6-by-10-foot traveling showcase that features the company’s latest shrink-fit toolholders, a shrink-fit machine and a tool-balancing machine. “The goal of the truck is to bring our showroom to the customer,” says Product Manager Dan Sanchez. “It allows us to show customers how the machines work, and it allows them to actually use the machines and get a comfortable feel for how they work.”

Mr. Sanchez says the vehicle provides an excellent follow-up for trade show activities, since show attendees often are too busy during the show to focus too much on one exhibitor. In addition, by bringing the vehicle and its equipment directly to a customer’s location, demonstrations can be done on their own tools. “As far as the balancing machine is concerned, we can take their existing toolholders and check how well they’re balanced right there at their facility,” Mr. Sanchez explains. “If need be, they can correct the imbalance and do an apples-to-apples comparison, running a balanced tool and an unbalanced tool.”

Mr. Sanchez disagrees with the idea that only high-speed cutting applications can benefit from balanced tools. “The benefits of balancing are greater at high rpm, but there are always benefits to balancing,” he explains. “Unbalanced tools can cause tool wear and vibration that can damage spindles, resulting in a less-than-perfect finish.”

In addition to customer convenience, the demonstration truck has other advantages. It allows customers to get hands-on experience with the Haimer equipment and exposes them to the entire spectrum of the company’s products.

“It’s very difficult to express to the customers how easy our machines are to use just by showing them a catalog,” Mr. Sanchez continues. “The truck is invaluable. We’ve sold a lot of machines because we were able to let the customers actually use them. A lot of times, we bring the truck to a customer who is interested in either balancing or shrink fitting, and they see the whole demonstration and become interested in both.”

The new demonstration truck replaces an aging Mercedes-Benz truck that was shipped to the U.S. several years ago by Haimer USA’s parent company, Haimer GmbH, in Germany. Last May, when it was time for that original vehicle to be decommissioned, Haimer USA opted for a larger, domestically manufactured chassis and updated the technology in the demonstration area.

“We’ve come up with so much more technology and advancements with our products and introduced new products, so we wanted the new demo truck to demonstrate all of our capabilities as a company,” Mr. Sanchez says. New software was installed on the balancing machine and a new-generation shrink-fit machine with an adjustable coil was added, as well as a tool-clamping device and some of Haimer’s new shrink-fit chucks and precision collet chucks.

The new demonstration vehicle hit the road in October and is traveling throughout various parts of North America. It spent its first months of service in Texas, and then moved to the Southeast region in January and February. The truck has now made its way up the east coast for follow-up activity from EASTEC. Next it will move into Canada and the Midwest.

To learn about other innovative ways Haimer is spreading the word of its products while reaching out to the manufacturing community, visit the article highlighted in the “Editor Picks” section to the right.

Related Content

Succession Planning: Three 15-Minute Activities to Start Preparing for Tomorrow

Succession planning is planning for the future success of your business.

Read MoreCNC Machine Shop Employment Positions to Consider Beyond Machine Operators

Many machine shops have open machine operator positions to fill. But does it make sense for shops to also seek automation engineers, IT managers and assembly personnel?

Read MoreVideo Tech Brief: CNC Screw Machines a Solution for Overcoming Labor Shortages

CNC screw machines can exceed job shop productivity and enable manufacturers to overcome perpetual employment gaps.

Read MoreJob Candidate Questions and What They Tell Us

Individuals who ask thoughtful, original questions in the interview set themselves apart.

Read MoreRead Next

New Equipment Gives Students A Learning Boost

Haimer USA entered a partnership agreement with the Institute for Manufacturing Productivity at York Technical College (Rock Hill, S.C.). By supplying equipment to the school, the company gives students, and those already working in the manufacturing industry who receive training at York, exposure to processes that can make them and their employers more successful.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)