Automatic Lathe Maximizes Number of Operations in One Machine

PMTS 2023: Esco’s Escomatic D6 CNC Ultra automatic lathe makes it possible to machine the front and back of the workpiece simultaneously.

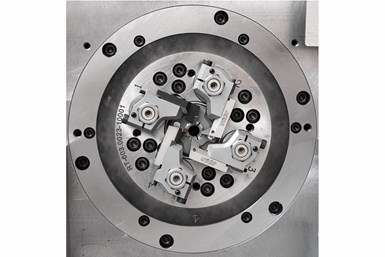

Esco’s Escomatic D6 CNC Ultra automatic lathe features a fixed material and tool carrier crown rotated around the material. Photo Credit: Esco

Esco’s Escomatic D6 CNC Ultra automatic lathe maximizes the number of operations in one machine to streamline and increase production. The tool head rotates up to 12,000 rpm and has three cutting tools that can be controlled separately, as needed, to offer more possibilities and simplify the process. The lathe is capable of handling a variety of materials for the production of small-diameter parts.

The lathe makes it possible to machine the front and back of the workpiece simultaneously. The DUF front machining unit consists of three axial spindles designed for drilling, milling and tapping. The counter spindle with a C-axis and the DUF system are each mounted on a table equipped with separate CNC axes, with a displacement of 40 m/min.

After cutting off the workpiece, three axial spindles and one transverse spindle can perform secondary machining operations at a speed of 18,000 rpm, enabling high-performance secondary operations. Everything is controlled by a Pegasus/Beckhoff CNC control for more flexibility and ease of use.

The machine can handle material diameters between 0.3 mm and 4 mm, and a maximum 80-mm part length (maximum straightening length). Machining is carried out from torches (crowns), if necessary at a continuous rate of 24 hours a day. The production is suitable for both machining a series of parts and production of pilot series.

The original escomatic technique, assisted by a Pegasus CNC control from Beckhoff, uses short escomatic chisels equipped with commercial inserts. The machine uses both original escomatic and commercial guns. The maximum speed of the toolhead is 12,000 rpm, which means production cycles are fast and machining times are reduced.

Related Content

-

Shop Optimizes its Swiss-Turning Flexibility

Paramount Machine uses various Swiss-type lathes, some with a B axis, to produce parts more effectively than it did on conventional chucker lathes. Today, nearly every job under 1.5 inches in diameter runs across those machines even if the batch size is a mere 5 pieces.

-

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

-

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)