Broaching Tools for Keyways, Internal and External Profiles

Eastec 2023: The REV motorized broaching tools are well suited for machining simple keyways or internal and external profiles, both teeth and splines.

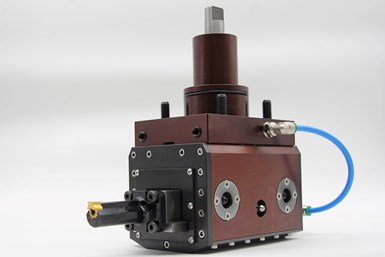

Platinum Tooling is the North American importer of REV motorized broaching tools. REV S.R.L., located in northern Italy, is the manufacturer of broaching solutions for CNC live tool lathes. These tools are well suited for machining simple keyways or internal and external profiles, both teeth and splines.

The company says it is possible to achieve many common profiles, including square and hexagon as well as custom profiles when required. Depending on the material, keyways can be machined up to 16 mm.

The REV motorized broaching tool is designed for maximum rigidity, long insert life and excellent finish. Well suited for high production runs, these tools are easy to install and said to offer a fast and efficient processing time using a single machine setup. The employment of these motorized broaching tools eliminates the need for a secondary operation which can result in considerable cost savings.

The tool has a Y axis adjustment with a range of ±0.5 mm to correct alignment on lathes without a Y axis. In addition, Rev broaching tools are equipped with a coolant delivery system to supply coolant to the tip of the cutting tool. REV broaching tools will be sold by Platinum Tooling’s network of distributors and representatives throughout North America.

Look for these and other tooling options at Booth 5148 at Eastec 2023.

Related Content

-

Producing Micro Screws for the Watch Industry

Cutting tools play a key role in machining tiny screws on Swiss-type lathes for this Switzerland-based watch manufacturer.

-

The Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

-

Data Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

.png;maxWidth=300;quality=90)