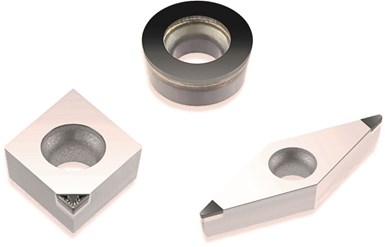

Carmex Inserts Designed for Challenging Machining Applications

Carmex diamond PCD, CVD-T and PCBN turning inserts designed to increase efficiency and productivity for difficult materials.

Carmex Precision Tools’ diamond turning inserts are designed to deliver higher productivity and greater efficiency in machining non-ferrous and hard materials faster and more effectively than grinding or ceramics. According to the company, the diamond PCD inserts excel in the machining of nonferrous materials, including high-silicon aluminum, copper and brass alloys, magnesium, carbon fiber-reinforced plastics and composites.

Similarly, the CVD is designed for machining aluminum and magnesium alloys, high-silicon aluminum, precious metal alloys, plastics with abrasive fillers, tungsten carbide, and ceramic green compacts. The company says an advanced chip breaker reduces heat generation and energy consumption.

The diamond PCBN inserts are said to deliver high-precision performance and excellent surface finish in materials including hardened and heat-treated steels up to 72 HRc, high-speed steel (HSS), high alloyed steels hardened to 45 HRc and higher, super nickel-based alloys, grey cast iron, ductile and graphite.

The diamond inserts are available in both one and two cutting edge configurations to deliver both higher performance and longer tool life.

Related Content

-

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

-

Shop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

-

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

.png;maxWidth=300;quality=90)