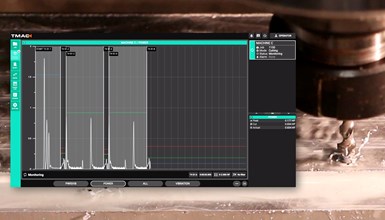

Caron’s TMAC System Offers Real-Time Tool Monitoring

Monitoring system accurately monitors tapping cycles.

Caron Engineering’s Tool Monitoring Adaptive Control (TMAC) system offers a universal interface that provides a real-time connection with nearly any CNC on the market. According to the company, the system uses a high-precision, auto-scaling power sensor to measure the load on the tool and compares it to the user-defined limits to determine wear. TMAC’s direct interface to the CNC is said to allow the system to make real-time adjustments to feeds and speeds, automatically expires worn tools, and stops and retracts tools instantaneously in the event of breakage or other extreme conditions. All of this is driven by an intuitive user interface to view all live cutting data as it happens, with all cuts recorded to view and analyze at any time.

The company says the system can also accurately monitor tapping cycles, which are otherwise difficult to monitor due to power spikes caused by the tool’s forward and reverse actions. It is said monitoring tapping cycles is easy to set up through use of time increments in TMAC. The system learns the power of the tap as it winds into the materials. During monitoring, TMAC can isolate just the cutting portion of the tap (in its forward cutting motion). As the tap unwinds from the material, the monitoring goes into a “hold mode,” while ignoring any spikes in data. TMAC measures the wear of the tool and alarms the machine when excessive wear or breakage occurs, using either tool wear linear or area-under-the-curve limits. Use of a pre-load signal creates precise start and stop timing from the CNC, which synchronizes monitoring based on specific programmable logic controller (PLC) functions, according to the company. TMAC will ignore unwanted power spikes due to reversing the tap and unwinding out of material. By using precision power sensors, TMAC can monitor a wide range of taps. With smaller taps, the auto-scaling sensor capabilities make it possible to register even the slightest power signals and monitor all cutting operations. With the newest version of TMAC (version 3.0), users can even label the cuts as specific features on the part.

Related Content

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

-

Streamlining Part Measurement, Data Collection Processes

When collecting measurement data automatically with a wireless data collection system, manual errors can be eliminated ensuring data accuracy and traceability.

-

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

.jpg;maxWidth=300;quality=90)