CGTech Software Update Features Interactive Capabilities

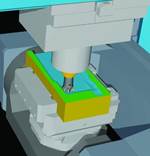

CGTech releases version 9.5 of its independent Vericut software, designed with a custom tool summary, heat display, interactive simulation timeline and more.

CGTech releases version 9.5 of its Vericut software. Vericut specializes in CNC machine simulation, verification and optimization across processes like metalcutting, additive manufacturing, hybrid manufacturing and composites. It is an independent, standalone software that can seamlessly integrate with all major CAM and tool management systems, as well as existing NC programs- even those that have been edited or created by means other than CAM.

In addition to improvements within the core product, Vericut 9.5 focuses on improving the user experience. It is said to have automated NC program optimization, while maximizing production efficiencies across multiple processes and minimizing downtime.

According to the company, highlights of Vericut 9.5 include:

- Tool summary and tool wear: Customers can use the heat map display (in Vericut’s tool summary window) to see the wear pattern on their milling and drilling tools. A combination of colors and messages can be used to understand how each tool was used and the effects of each cut on the tool. Tool life can be tracked by assigning wear limits to cutters for a variety of machining factors, such as cutting time, material removal volume or cutting distance, to get notified when a tool is nearing expiration.

- CNC machine connectivity: CNC machine connectivity can enable Vericut to connect directly to your machine to see real-time data in Vericut before, during and after machining has taken place.

The Postcheck capability within the CNC machine monitoring module enables users to review monitored data that was archived from the NC machine within a Vericut simulation. This feature can enable users to observe how well the machine ran, as well as identify when and where spindle or feedrate override adjustments were applied, machining was paused or if the emergency stop was used during machining of a specific part.

Vericut 9.5 also introduces connectivity support for NC machines with Okuma, Siemens and Heidenhain controls.

- Interactive CSYS and model transformations: Vericut 9.5 provides tools for working with coordinate systems. Interactive transform menus can enable users to interactively translate and rotate coordinate systems, components and models faster and simpler. Visual cues show how pending transformations will be applied, which is designed to give users confidence to know the moved object will arrive at the desired location.

- Enhancements to interfaces: Vericut 9.5 is said to add support for the latest released CAM versions as well as bring a number of enhancements and capabilities to its CAM interfaces to automate as many picks as possible from within the interface. The CAM interfaces are also being updated to support more advanced types of tools for simulation.

- “Smarter” learn mode for optimizing: Vericut’s “Learn” mode can evaluate machining performed by each cutting tool, then auto-configure optimization to increase cutting performance and efficiency. Vericut 9.5 has a “smarter” learn mode, with ability to learn from cutting tools used multiple times (for example, roughing, semi-finishing, finishing and so on), then use the learned information to optimize those tools per each machining operation it performed.

- Interactive simulation timeline: The simulation timeline (in the tool use window) is interactive with the NC program viewer and NC program review. It has been enhanced to account for all time used by the machine as commanded by NC programs used to make the part. Color-coded markers show when errors (red), warnings (orange) and other events occurred during the simulation. Click the NC program review icon and then click directly on a marker in the timeline to review the error in the simulation and investigate exactly where it occurred in the program.

Related Content

The Value of CAD/CAM and Cutting Tool Manufacturers Working Together

Overall machining efficiency can be increased when software and tooling companies combine to tackle machining challenges.

Read MoreWho Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.

Read MorePrecision Machining Technology Review: September 2024

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more.

Read MoreHack-Proof Your Shop: Production Machining’s 6 Must-Read Cybersecurity Articles

October is cybersecurity awareness month and Production Machining wants to help you make your shop hack-proof.

Read MoreRead Next

United Technologies Optimization Tool Added to Vericut

The new feed rate optimization tool is based on machining trials within UTC. The commitment of an established software company will help this OEM bring cost-saving technology to its suppliers.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)