Company Expands Horizontal Travel on Optical Comparator

L.S. Starrett expands horizontal X-axis travel on the HB400 benchtop optical comparator from 12" to 16" to measure large parts on its workstage.

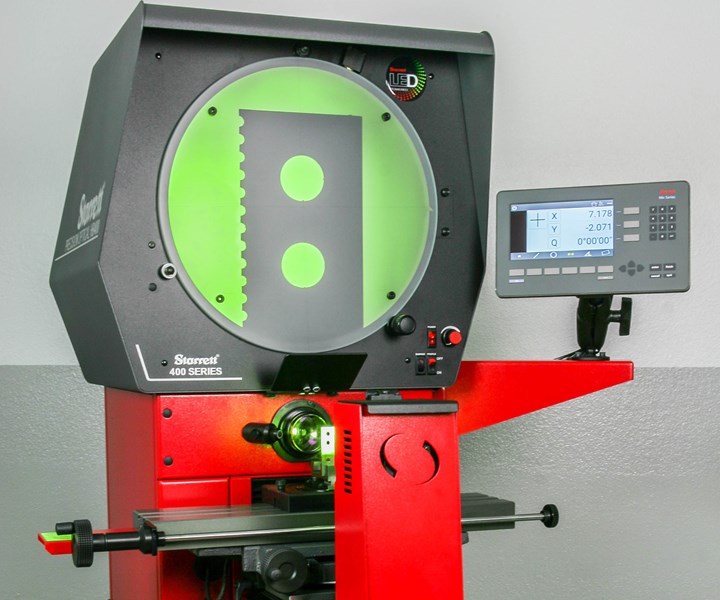

L.S. Starrett has expanded the horizontal X-axis travel on the HB400 benchtop optical comparator from 12" to 16" (300 mm to 400 mm), providing users the versatility to measure large parts on its workstage.

The comparator features a 16" (400-mm) diameter viewing screen, a 16" (400-mm) horizontal travel, a 6" (150-mm) Y vertical travel, a 2" (50-mm) focus travel and a 110 lb. (49.9 kg) workstage load capacity. The HB400 also has all-metal construction with a hard-anodized stage tooling plate, LED profile and surface lighting rated to 50,000 hours, touchscreen operation and a linear encoder glass scale on both X and Y axes. Also includes a digital protractor for angle measurement of 1-ft. resolution via Q-axis readout.

The HB400 has a single, bayonet-style lens mounting system that accepts a choice of six fixed interchangeable lenses, as well as OV2 Zoom or TOV2 fixed telecentric magnification video camera systems. Available with MetLogix M1 tablet, M2 or M3 measuring software (when using OV2 and TOV2) PC or digital readout systems.

Related Content

-

The Advantages of Automated Shopfloor Gaging

This “parallel kinematic” gage offers the opportunity to automate and improve machining process control for shops endeavoring to move from sample inspection to 100% inspection.

-

Automated Inspection Transforms Medical Manufacturer’s Quality Control

Manual steps for part inspection have been eliminated with a new CMM process using more advanced software and strategies such as using a combined scanning/touch-trigger probe.

-

How Well do You Know Granite Surface Plates?

Here are some tips for choosing, maintaining and customizing a granite solution that will best meet your shop’s particular inspection needs.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)