Diatool Top Speed Ring Provides Fast, Precise Reaming

The TSR is well suited for long production runs of large diameter bores, precision reaming of heavy equipment components or any application requiring precise and repeatable bore sizes.

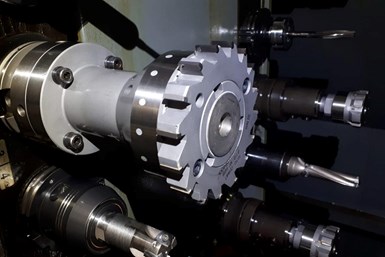

Monaghan Tooling Group’s easy-to-use Diatool Top Speed Ring (TSR) modular reaming system is said to achieve up to 70% faster feed rates with out-of-the-box functionality. With up to four additional cutting blades, this design enables faster machining as well as increased tool life to achieve unrivaled performance and cost-efficiency.

The multiblade design features uneven spacing of cutting edges to create exceptionally round and cylindrical bores. The TSR comes set to size and requires no additional setup, delivering ready-to-cut functionality. Moreover, the holders are equipped with internal coolant as a standard feature.

The Diatool TSR covers a diameter range of 50.000 mm to 225.000 mm (1.9685" to 8.8583"), making it an optimal solution for a diverse range of precision reaming applications. It is well suited for long production runs of large diameter bores, precision reaming of heavy equipment components or any application requiring precise and repeatable bore sizes.

Designed with durability in mind, the solid TSR offers straight or left-hand fluted options, ensuring the optimal bevel lead geometry can be utilized for performance and chip control throughout its long service life. It also supports Cermet, carbide or PCD blades and a full line of coating options, enabling optimum reaming results across a variety of part materials. The TSR holders are available in cylindrical shanks or module connections to enable runout compensation or for use with standard hydraulic holders.

In addition to long service life, the Diatool TSR has an economical design with rings that can be reconditioned numerous times to original equipment manufacturer (OEM) specifications, achieving the same tool life as a new reamer. This reusability makes the Top Speed Ring both efficient and cost-effective.

Related Content

-

Parting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

-

Producing Micro Screws for the Watch Industry

Cutting tools play a key role in machining tiny screws on Swiss-type lathes for this Switzerland-based watch manufacturer.

-

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

.png;maxWidth=300;quality=90)