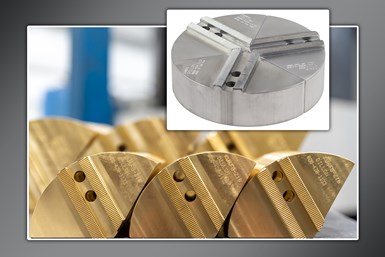

Dillon's Full-Grip Chuck Jaws Reduce Part Distortion

Dillon full-grip jaws are ideal for high-speed machining, as well as precision boring, tapping, drilling and finishing across most industrial markets.

Dillon Manufacturing’s line of full-grip jaws are available in various materials in both standard and custom configurations to suit varied workholding applications.

With maximum contact area for a solid gripping surface, these full-grip jaws are said to provide more friction for drive with reduced part distortion. Manufactured from 6061 aluminum, 1018 steel, cast iron and brass, Dillon full-grip jaws will not mark or mar the workpiece surface.

Standard sizes are available to up 32" in diameter. Custom designs available with special heights, diameters, materials and configuration can securely grip any workpiece, including a matching serration location which is exactly perpendicular to the slots. In addition, these special full-grip jaws can reduce and simplify setup times. Dillon says its full-grip chuck jaws are made in the U.S. with industry-leading lead times. They are well suited for high-speed machining, as well as precision boring, tapping, drilling and finishing across most industrial markets.

These wraparound-type top jaws distribute more of the gripping pressure across the workpiece, reducing part distortion. Dillon standard and custom full-grip jaws are available in serrated, tongue and groove-serrated, Acme-serrated and square-serrated designs.

Related Content

-

Starting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.

-

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

-

Data Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)