Emag Twin Spindle Lowers Gear Machining Costs

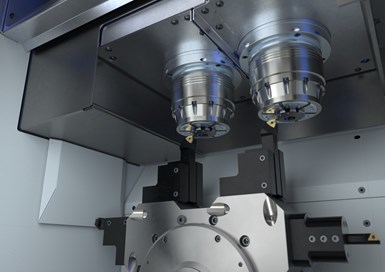

The VL 1 Twin-spindle pick-up turning machine simultaneously machines two identical bevel gears at high speed within the same machining area.

Emag’s VL 1 inverted-vertical, twin-spindle turning machine simultaneously machines two identical bevel gears at high speed within the same machining area. Combined with a robot cell and swivel table that can easily load the machine, it can bring the cycle time for machining bevel gears down to 4.5 seconds, which can drastically lower production costs. The machine is designed to manage large quantities cost-efficiently, quickly and free of defects. According to the company, the machine is well-suited for soft and hard machining of a wide variety of bevel gears up to 75 mm in diameter (3"). It features two pick-up spindles (9.9 kW/136 Nm at 40% duty cycle) that are used to machine two identical bevel gears in parallel. The two spindles load and unload the machining area in just five to six seconds.

The next machining steps are then performed successively and in a single clamping operation with a total cycle time of about 25 to 40 seconds (depending on type and size of part). The average chip-to-chip time is just under six seconds. A special clamping solution reproduces the negative image of the component’s gearing and holds it firmly in place. Additionally, the VL 1 Twin is able to drill into solid material, which is how the bevel gear’s center bore is produced. The machine is designed for fast production and high output quantities, while significantly reducing the price per spindle with rigorous cost controls — contributing to low unit costs.

Related Content

-

Software Controls Chip Breaking in Thread Turning Operations

This cutting tool manufacturer has developed a software module for chip control of thread turning operations in virtually any CNC lathe, even for older machines, using specific tooling and software.

-

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

-

Shop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

.jpg;maxWidth=300;quality=90)