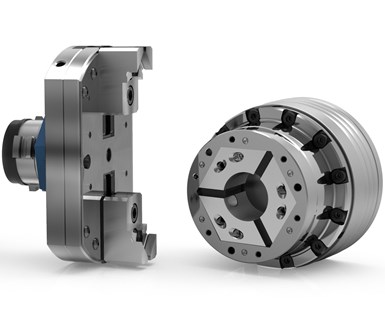

Hainbuch 2-Jaw Module Adapts to Clamp Cubic Parts

The 2-Jaw module delivers small alternative to large centric vice.

For cubic parts that are positioned centrically on machining centers and milling machines, Hainbuch’s 2-Jaw module adapter enables manufacturers to change over from clamping round parts to cubic ones in less than two minutes.

The 2-jaw module can handle turning applications up to 1,500 rpm. Due to its compact profile, it is well-suited as an alternative to large and heavy centric vises. The 2-jaw and 3-jaw module both use the Hainbuch collet chuck as their base. Changeover is possible without removing the collet chuck and realignment due to the Centrex quick-change interface.

According to the company, Hainbuch’s modular system enables a wide variety of workholding configurations to accommodate round, prismatic, small or larger components. The various workholding adapters can be installed in two minutes or less. Round workpieces are clamped from the outside with clamping heads (collets) within the collet chuck. Larger diameter workpieces, beyond the capacity of the collet chuck, can be clamped with the 3-jaw module.

Related Content

-

Shop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

.png;maxWidth=300;quality=90)