Haubex's Automatic Vise Change From Tool Magazine

IMTS 2022: Lang Technovation’s Haubex is a simple automation solution for small batches that transforms the tool magazine into an automation system.

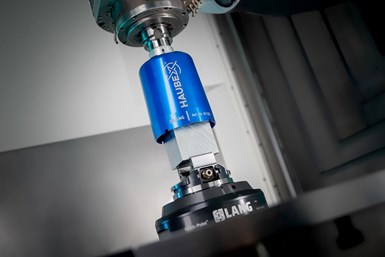

Haubex system transporting new production part. Photo Credit: Lang Technovation

Lang Technovation says its Haubex is a flexible and cost-effective automation solution for small batches from batch size 2 that transforms the tool magazine into an automation system. The heart of the system is a workholding hood, which serves as a carrier system for the clamping device and the workpiece blank and is stored in the tool magazine.

The system is said to make it easy to increase efficiency in manufacturing by productively filling breaks, creating additional time windows for alternative, value-adding activities or extending working hours by enabling the machine tool to continue unmanned production after the end of work.

Related Content

-

High-Volume Machine Shop Automates Secondary Ops

An Ohio contract shop added a compact, self-loading CNC lathe to perform unattended secondary ops on a part for a key customer rather than running it on a manually loaded chucker.

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Replace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)