HyperMill CAM Software for Hybrid Manufacturing

IMTS 2022: The hyperMill CAM software features an additive manufacturing capability option, which is said to provide efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

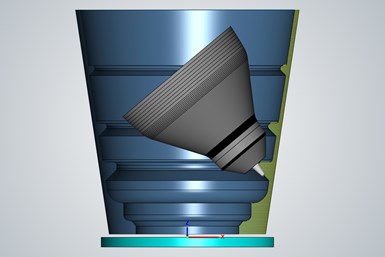

HyperMill Additive Manufacturing controls the material application on this nozzle cross section with a nonconstant thickness. Photo Credit: Open Mind Technologies

Open Mind Technologies’ hyperMill CAM software features an additive manufacturing (AM) capability option which is said to provide efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

The company says it has optimized its hyperMill AM technology to boost the efficiency, precision and process reliability of additive and hybrid manufacturing.

For highly complex 5-axis simultaneous processing, the software enables an array of flexible options for directed energy deposition processes (DED) and wire arc additive manufacturing (WAAM), the company says. Both laser-based powder nozzle machining heads and WAAM can be controlled using hyperMill AM for selective material deposition, as well as conveniently programming and automatically simulating the path for collision avoidance.

Key additive applications include repair of damaged components, cladding of additional surface skins or the creation of new components from a substrate. This also creates totally new options for combining different materials, such as when high-quality material layers need to be applied to carrier materials.

Related Content

-

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAD/CAM system. Here’s how the company succeeded despite the newness of it all.

-

Precision Machining Technology Review: December 2023

Production Machining’s December 2023 technology showcase includes some of the latest technology from Sandvik Coromant, Nikon Metrology, The L.S. Starrett Co., Walter USA, Kennametal and SolidCAM.

-

Precision Machining Technology Review: August 2024

Production Machining’s August 2024 technology showcase includes some of the latest technology from SW North America, Tsugami, Siemens, Select Manufacturing Technologies, Hurco and ECI Software Solutions — all on display at IMTS 2024.

.jpg;maxWidth=300;quality=90)