Inovatools’ Primus End Mill Offers Optimized Chip Control

Aluminum Roughing End Mill features internal cooling and multiturning to deliver consistently quiet, low-vibration, energy-efficient performance at extremely high feed rates.

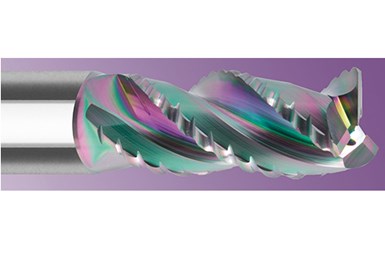

Inovatools’ Primus HPC aluminum roughing end mill

Inovatools’ Primus HPC aluminum roughing end mill is part of the company’s ta-C series, which is designed to provide thin, hard, smooth performance thanks to a ta-C coating that helps shops achieve higher productivity and quality.

With internal cooling and multiturning capability, the Primus is equipped to deliver consistently quiet, low-vibration, energy-efficient performance at high feed rates. To this end, the tool has a special knurled section with optimized chip control as well as the ta-C high-performance coating. This enables it to eliminate the usual problems in cutting aluminum, such as high adhesion tendency with built-up edges, welding deposits, chip caking and burr formation.

The company says that the ta-C coating combined with the microgeometry in conjunction with the cutting-edge preparation makes the tool highly resilient to prevent microchipping. This defect-free, cutting-edge design considerably increases the Primus’ service life. This is supported by the entwined profile’s special chip separators. These break the aluminum chips quickly and at an early stage, and, thanks to large chip grooves, they can be rapidly transported away from the engagement zone with cutting fluid. Not only does this bring a high level of process security, but it also is said to ensure low-vibration running for high surface quality, even during HPC roughing. This means that Primus tools operate with minimal vibrations, even at exceptionally high feed rates. The three-edged Primus is available in diameters ranging from 6.00 mm to 20.00 mm, with internal cooling, multiturning and straight and Weldon shank designs.

Related Content

-

Data Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

-

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

-

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)