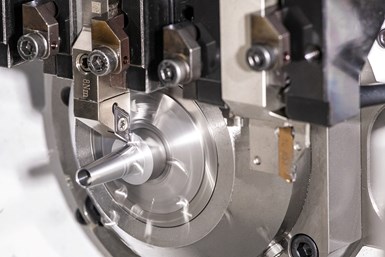

Iscar’s NeoSwiss Quick-Change Toolholders With Y-Axis Orientation

PMTS 2023: NeoSwiss from Iscar is a quick-change Swiss tooling system focused on rigidity and repeatability.

Iscar’s NeoSwiss modular quick-change toolholders line for Swiss-Type machines offers a variety of heads available for multiple machining operations, including turning, backturning, threading, grooving and parting. When developing the NeoSwiss line, Iscar focused on two main points: rigidity and repeatability. Changing heads can be done in seconds because of the rotary-wedge clamping mechanism. Iscar says this clamping mechanism provides extreme clamping forces, resulting in great machining stability. For head replacement, Iscar says the repeatability is at ±0.0008 inch.

All shanks and heads are produced with Iscar’s JetCut coolant-through capabilities and can be used with coolant pressures up to 2,000 psi. The majority of NeoSwiss heads come with two different coolant ports to reduce the heat in the cutting zone. One port is shooting from behind the rake face of the insert, which is said to help with chip control by quenching the chip as it forms, creating a chip that is more brittle and more apt to break. The second port is below the flank of the tool. Working in tandem, these two ports force coolant into the cutting zone from above and below the insert, extending tool life and providing better chip control, the company says.

The shanks, available in 0.500", 12 mm and 16 mm, have three different access points to connect the coolant to a machine. This results in compatibility with most Swiss machine manufacturers.

In addition to the many X-axis heads offered, Iscar also offers Y-axis heads in different turning and grooving configurations. Both X- and Y-axis heads connect to the same shank, and both have the coolant features mentioned above.

Related Content

-

Tips for Choosing the Right Toolholder for High-Speed Machining

Here is some advice for shops hoping to maximize their efficiency performing high-speed milling operations.

-

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

-

Zoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)