Mastercam 2021 Designed to Increase Productivity

Mastercam 2021 improves automation, efficiency, connectivity and precision.

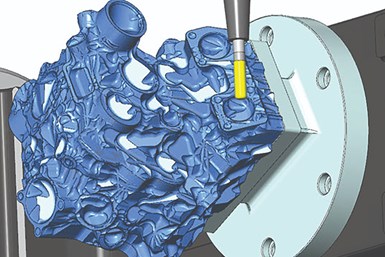

CNC Software Inc.’s Mastercam 2021 is designed to increase machining productivity and reduce overall production costs with faster, more flexible multi-axis improvements as well as enhancements in turning and turning-related applications, and advances in speed and safety.

According to the company, the CAD/CAM software streamlines the manufacturing process from job setup to completion. Expanded multi-axis pocketing combines efficient pocket cutting with a focus on finishing with accelerated finish tools, automatically maintaining the correct tool contact within defined parameters.

Users can analyze and modify the UV direction on surface models, expanding the power and flexibility of multi-axis flowline milling tool paths. The 3+2 Automatic Roughing tool path automatically makes multiplane 3-axis roughing tool paths by evaluating the model and stock, creating a cut, calculating what remains, and repeating the process until roughing is complete. The software also expands the support for modeling chucks and chuck jaws, enabling users to define them by selecting a solid model.

Mastercam Mill-Turn supports collet chucks as individual component types which expands the range of machines that can be directly supported. Mill-Turn Simulation has been added to the Mastercam Simulator interface so users can experience Mill-Turn Simulation with the same interface tools as Mastercam Simulator. Also, the Swiss machining solutions combine Mastercam Mill and Mastercam Lathe with specialized post processors. This adds machine-specific controls inside the Mastercam interface, which is said to deliver accurate G-code for a wide variety of Swiss machines.

Advanced Drill is a customizable multisegment drill cycle that is useful for spot drilling, deep hole drilling and back spot facing, and each segment of the drill cycle can be defined and customized. When using tools with a tip angle, the Chamfer Drill toolpath chamfers holes after calculating the correct depth based on the desired width or depth, and enables users to select holes of different diameters or sizes (or that lie in different planes) and machine them in a single operation with a single tool. The Wrap option enables users to create small bounding boxes, while the Check Tool Reach function enables users to check tools and holders against the selected model geometry to view where the tool can and cannot reach.

Related Content

-

Precision Machining Technology Review: December 2024

Production Machining’s December 2024 technology showcase includes some of the latest technology from Hexagon, Kennametal, SmartCAM, Horn and SMW Autoblok.

-

Mastercam 2024 Integrates Sandvik Coromant CoroPlus Tool Library

The integrated library enables users to work faster when importing tool geometries and cutting data.

-

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

.jpg;maxWidth=300;quality=90)