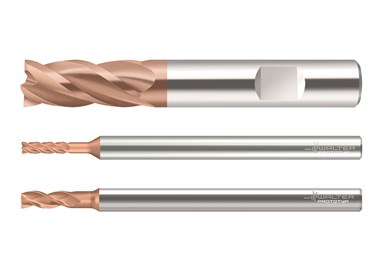

MC232 Perform Line of Solid Carbide Milling Cutters

The cutters have a corner radius for improved approaches, longer tool life, and greater edge stability.

Walter’s MC232 Perform line of solid carbide milling cutters feature a corner radius and reduced neck. Solid carbide milling cutters with corner radii allow improved approaches to individual component geometries. It also improves the tool life of the milling cutter, as the edge stability is increased.

The reduced neck, in turn, makes the milling cutter more flexible, as it can be used with an even wider variety of cutting depths. MC232 Perform line, with diameter sizes ranging from 1/8” to ¾” and 2- to 20-mm, can be used for all typical milling applications (shoulder, slotting, pocket milling, helical plunging and ramping) and are suitable for a variety of materials.

Users also benefit from other features of the Perform line, such as the high level of cost efficiency for small and medium batch sizes. Application of the milling cutter line include steel, stainless and cast iron. They are of particular benefit to job shops and manufacturers that are frequently changing orders or quantities.

Related Content

-

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

-

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

-

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)