Modular Tooling System Features Coolant-Through Design

System enables faster tool changes as well as internal coolant delivery directly to the cutting edge.

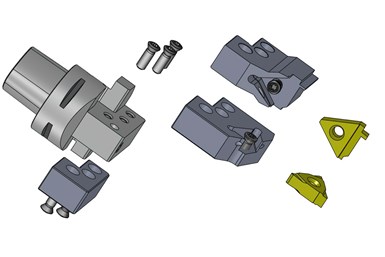

Form cutting tool manufacturer Schwanog has developed the MSIK modular tooling system by which the coolant is supplied internally and directly to the cutting edge through the base body and cartridge.

The company explains that modular tooling systems are increasingly being used in the metal cutting industry because they offer significant advantages over conventional clamping systems. The basic principle and central advantage are that the tool holders can be preset prior to the machining process and thus be available for fast installation on the machine. They are characterized by high flexibility and a substantial reduction in tool inventory which leads to reduced tool costs. Tool changes via this type of toolchanger are faster, more reliable and easier than manually changing inserts in the machine.

With the MSIK, different standardized cartridges for grooving can be used on the common system base body that includes machine interface. The interface to the cartridges is bolted to the side of body ensuring a stable and secure connection. Cartridges are available for the company’s insertable/indexable WEP and PWP tooling systems, which are ground according to customers’ drawings and said to ensure maximum efficiency.

The base body is offered with polygonal/Capto ISO 26623 interface in sizes C3, C4, C5 and C6 as well as HSK-T63 ISO 12164 interface. These are available with and without serration (without serration shortens the overall length). ISO 26622 TS interfaces are also offered. Right, left and neutral body versions are available as are special, customer-specific designs.

Related Content

-

Zoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

-

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

-

Seco Tooling Lineup Promotes Optimized Part Processing

The company’s expanded tooling lineup is aimed at applications ranging from general ISO turning to high-volume hard turning and deep-hole drilling.

.png;maxWidth=300;quality=90)