Open Mind hyperMill Software Expands Finishing Capabilities

Open Mind Technologies introduces hyperMill 2019.1, a version of its comprehensive CAD/CAM software.

Open Mind Technologies’ hyperMill 2019.1 has a range of features including an expanded finishing module in the Maxx Machining Performance Package, process optimizations such as a thread milling module, a function for reducing calculation times, tool database flexibility, and CAD optimization.

The software’s five-axis Prismatic fillet finishing function enables the geometry and automatic inclination of barrel cutters to be applied similar to high feed cutters, using a plunging and pulling movement at high feed rates. Maximum performance is said to be attainable using conical barrel cutters. Ball or bull nose end mills are also utilized with this milling strategy.

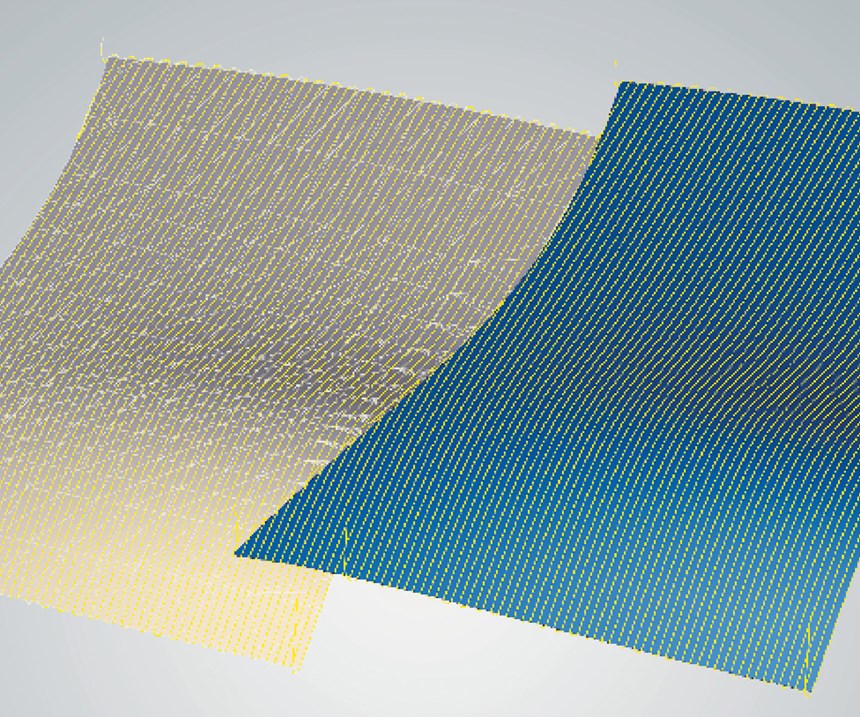

According to the company, the Profile Milling technique has an option that improves the quality of machined surfaces. Traditional CAM software processing uses a close-approximation mesh surface for machining calculations. A benefit of the mesh approach is to standardize CAM processing, even in cases when the design model has imperfections. The company has implemented techniques in the software for machining directly to the model surface, which is said to improve surface finishes.

Among the process improvements, the updated thread milling module is said to be easy to program and supports a number of thread milling types, while simplifying selection and milling direction options. Also, recalculation cycles are no longer required when job I.D. numbers are changed or when fixture positions change. In addition, users have the option to individually expand the tool database, enabling users to store order numbers, pricing and tool life detail.

Finally, hyperCAD-S includes polyline management, enabling CAD functions such as lengthening or shortening to be applied by the polylines element type. Polylines can also be machined similar to all other elements, with trim, join, orient or select.

Related Content

-

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

-

Precision Machining Technology Review: December 2023

Production Machining’s December 2023 technology showcase includes some of the latest technology from Sandvik Coromant, Nikon Metrology, The L.S. Starrett Co., Walter USA, Kennametal and SolidCAM.

-

Hexagon AI-Powered CAM Software Streamlines Part Programming

The ProPlanAI CAM programming tool is designed to help machine shops achieve operational excellence at scale.

.jpg;maxWidth=300;quality=90)