Renishaw Fixture-Modeling Software Streamlines Setup Process

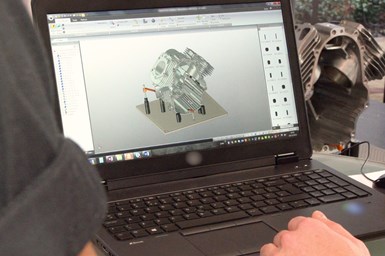

The FixtureBuilder 3D software enables fast creation and documentation of advanced, CAD-based, metrology fixturing setups.

Renishaw’s FixtureBuilder 3D fixture-modeling software enables fast creation and documentation of advanced, CAD-based, metrology fixturing setups for repeatable and productive part inspection. Users have access to the full catalogue of Renishaw metrology fixturing components when designing and documenting their modular fixturing setups.

Renishaw’s FixtureBuilder software features an intuitive interface, complete with component libraries, drag-and-drop functionality and a user-friendly constraint mechanism. Its also features full CAD compatibility and custom libraries, and the software’s “Build It” function automates the generation of work instructions and bill of materials for each fixture setup. This simplifies the purchase of fixturing components and helps users to meet quality standards.

According to the company, FixtureBuilder 8.1 enables the design of fixturing setups in seconds. It exports them to the inspection programming software of choice, using common file formats like IGES, SAT and STEP to ensure seamless functionality and compatibility with industry-standard inspection programs and applications.

FixtureBuilder 8.1 is available via a subscription service, and users receive a complimentary 12-month subscription to the software when they purchase qualifying metrology fixturing products or bundles.

“Our fast and flexible FixtureBuilder software is a powerful addition to any manufacturer’s inspection workflow,” says Will Paul, product marketing manager. “The weakest link in an inspection process is often the ability to design and document comprehensive fixturing set-ups with ease and speed. FixtureBuilder gives our customers confidence in the positioning of their parts.”

Related Content

-

The Value of CAD/CAM and Cutting Tool Manufacturers Working Together

Overall machining efficiency can be increased when software and tooling companies combine to tackle machining challenges.

-

Who Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.

-

Precision Machining Technology Review: December 2023

Production Machining’s December 2023 technology showcase includes some of the latest technology from Sandvik Coromant, Nikon Metrology, The L.S. Starrett Co., Walter USA, Kennametal and SolidCAM.

.jpg;maxWidth=300;quality=90)