Sinker EDMs Feature AI Adaptive Control Technology

The artificial intelligence adaptive control technology is said to help optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

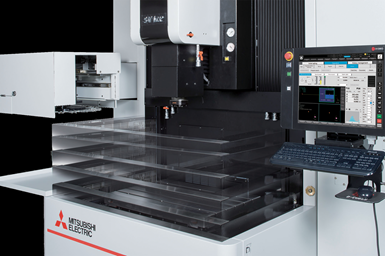

Photo Credit: MC Machinery

MC Machinery’s latest EDM and precision milling technology includes wire and sinker EDMs, machining centers and automation. The company, a subsidiary of the Mitsubishi Corp., is a supplier and servicer of fabrication and milling equipment, including Mitsubishi lasers, EDMs and automation systems.

The new Sinker EDMs feature artificial intelligence (AI) adaptive control technology. The company says the Mitsubishi SV12P and SG12 sinker EDMs optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

The AI technology is said to make logical use of condition-monitoring data. For example, these new machines can diagnose real-time problems within the burn and directly modify specific parameters for a stable and accurate output. This is said to enable machine operators of all experience levels to produce quality results in complex cavities and shapes.

Because the AI technology analyzes current sensor data to determine optimal conditions, it is said to reduce overall electrode wear and costs. By monitoring these parameters, the machine operates more efficiently and can more accurately predict machining times, the company says.

Related Content

-

4 Bright Ideas for Effective Lights-Out Machining

Adopting lights-out machining involves considerations when a machine shop decides to move forward with the process. Here are some tips to a successful implementation.

-

Tips for Troubleshooting and Repairing Chip Conveyors

A nonfunctioning chip conveyor can cause a high-production machine to be down for an extended period of time. Here is some troubleshooting advice if you’re having issues with your chip conveyors.

-

Unattended Production Takes More Than the Most Capable CNC Machine

Process planning and reliable peripherals are key to successful lights-out manufacturing.

.png;maxWidth=300;quality=90)