TDM Tool Management Systems for Production Efficiencies

The company’s latest data management support for customers includes new data services and a cloud-based solution.

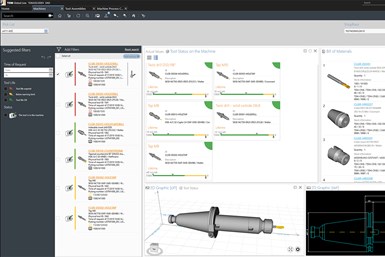

TDM Global Line 2023 offers, among other things, further developments in the toolroom. Photo Credit: TDM Systems

TDM Systems’ tool management systems include data services, direct machine connections and a cloud-based entry solution for tool management. According to the company, companies that do not digitalize will lose their competitiveness.

For over 30 years, TDM has offered software solutions for the efficient management of tool data and tools. Its core competence is offering machining companies a highly integrable solution which supports the entire process chain for the chip-making production and ensures that the tools always remain available.

The range of interfaces and partnerships to providers of manufacturing solutions is said to enable greater possibilities for users in digitalization of tool management and processes. Its latest data management support for customers includes new data services and a cloud-based solution.

The new Data Services are for both users and tool manufacturers. TDM says it has a dedicated data team with the expertise to take on the task of data creation for customers. Another service offers tool manufacturers a user-optimized digitalization of their data catalogs.

TDM Cloud Essentials is a cloud-based solution which does not require project management. Companies just need to register and can get started online. That implementation is possible for companies with an entry-level solution from TDM Systems and it does not require an IT installation. The Cloud Essentials is a cloud-based tool management system developed especially for small companies that have shied away from digital tool management until now.

It is said companies using these solutions can use these solutions to drive their digitalization forward and increase their efficiency, such as minimizing machine downtime. Users can use different communication options with the production machines to implement an automated transfer of tool data directly to the machine control. This means that the required tool data can be transferred without any errors and, by monitoring the tool life, tools can be retrofitted in a timely manner.

Related Content

-

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

-

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

-

The Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

.png;maxWidth=300;quality=90)