TX Series Pull-Down Chucks Have Constant Clamp Force at Higher Speeds, Feeds

SMW Autoblok’s 3-jaw pull-down chucks are fully sealed, featuring high accuracy and heavy-duty gripping for metal cutting applications.

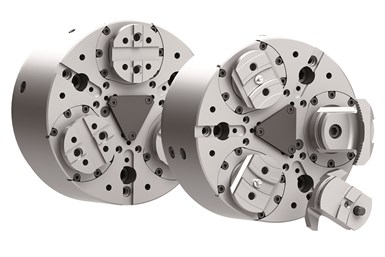

SMW Autoblok TX Series 3-jaw pull-down chucks

SMW Autoblok’s TX Series 3-jaw pull-down chucks are fully sealed, featuring high accuracy and rigid gripping. The chucks provide repeatability of up to 4 µm (0.00015") and precise, self-centering accuracy for heavy-duty metal cutting applications.

The TX Series features the TX-C (tongue and groove) and TX-RV (quick jaw change) models. Both versions are well suited for first and second operations, while providing exceptional parallelism, the company says.

A symmetrical master jaw design that disperses cutting forces over a wide area enables the chucks to hold their accuracy for a long lifetime to ensure consistent workpiece quality. The master jaw design also enables for ID and OD gripping with optimal stability and no changes that regular ball lock chucks require. Integrated centrifugal force compensation provides constant clamp force at higher speeds and feeds, vastly reducing production time.

The TX Series is fully Proofline sealed for greatly reduced maintenance and will run 24/7 for six months without adding additional lubrication. The TX-RV model features a quick-change top jaw for part families and both TX models have active pull-down for enhanced plane parallelism. The chucks are available in size ranges of 170, 210, 250, 315, 400 and 530 mm.

Related Content

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

Parting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

-

The Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.