Vericut 9.2 Simulates Machining, Additive and Hybrid Processes

Vericut software tests NC machine tool paths in an offline virtual reality environment with program verification that simulates material removal using a three-dimensional solid model.

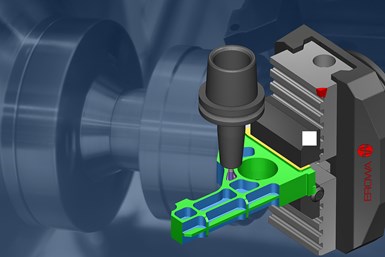

CGTech’s Vericut 9.2 includes more options for optimization.

CGTech’s Vericut software simulates CNC machining in order to detect errors, potential collisions or areas of inefficiency. Vericut 9.2 updates include speed increases for collision checking and overall performance, a 3DLive interface, improved cutting tool support and reporting enhancements. This version also incorporates hundreds of other customer-driven improvements and software requests.

This CNC machine simulation, verification and optimization software is said to simulate all types of CNC machining, additive and hybrid manufacturing processes. It operates independently, but can also be integrated with CAM systems. The software is designed to increase productivity and sustainability with features that boost manufacturing efficiency, help preserve machines and cutting tools, increase machine capacity, and dramatically reduce repair and scrap costs.

CGTech’s integrated simulation-optimization solution, Vericut Force, benefits from these latest enhancements to reduce machining times and extend tool life. It also helps prevent undesirable cutting conditions and improve part quality. Vericut 9.2 provides Force optimization users with more options for setting and adjusting optimization limits, as well as more comprehensive tooling data and greater customization options for graphs and reports.

The program also brings increased speed and improved accuracy to collision checking and overall performance, the company says. Users gain increased speed for deep concave collision penetration, turning operations (especially ID work on large parts) and collision checking between highly detailed models such as those having high triangle counts.

This version also includes more options for optimization. Programs can be optimized by setting target chip thickness and any combination of Force limits, including maximum force, maximum power and maximum tool deflection. Force can now also control the spindle speed. OptiPath has a new Learn mode that enables users to choose how aggressively to learn from current cutting results. Learn From Results in Graphs can send Force or OptiPath optimization settings or change optimization strategies for corresponding cutters.

Related Content

-

Lone Shop Machinist Benefits From Five-Axis CAM Modules

This California shop owner applies five-axis strategies for more efficient milling of parts with challenging geometries, free-form surfaces and deep cavities.

-

Precision Machining Technology Review: December 2023

Production Machining’s December 2023 technology showcase includes some of the latest technology from Sandvik Coromant, Nikon Metrology, The L.S. Starrett Co., Walter USA, Kennametal and SolidCAM.

-

Mastercam 2024 Integrates Sandvik Coromant CoroPlus Tool Library

The integrated library enables users to work faster when importing tool geometries and cutting data.