Walter Axial Grooving System Features Two Cutting Edges

The company says a key to the system’s success is the Walter Cut G1111-P holder and AF5 axial grooving chipbreaker system, which are said to deliver strength, reliability, optimum surfaces and high cost efficiency for axial grooving.

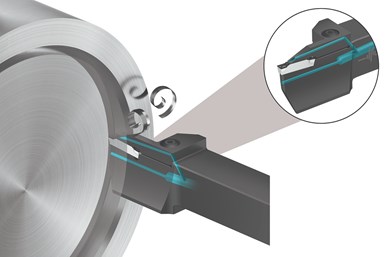

Walter’s Walter Cut G1111-P/GX24 AF5 axial grooving system features a G1111-P GX monoblock tool for axial grooving and groove turning with precision cooling. The company says the system provides reliability and longer insert life due to its reinforced cutting edge (such as with forged parts). It also incorporates precision cooling on the rake face with a coolant jet aimed at the clearance face for flushing the chips out of the axial groove.

The system handles axial grooves from diameters of 2.362″ (60 mm), cutting depths up to 1.299″ (33 mm) and insert width of 0.197″ (5 mm). The system is said to deliver maximum productivity and cutting parameters due to optimal cooling, strength and controlled chipbreaking, along with high cost efficiency due to two cutting edges. It is said axial grooving is effective when the groove depth is 1.5 times greater than the groove width, but to be successful axial grooving requires dedicated tooling and a dedicated chip control insert.

Another key to the system’s success is the Walter Cut GX24 grooving insert with AF5 Axial chipbreaker. This right- or left-handed asymmetric chipbreaker takes into account the variation in cutting speed on the outside and the inside corner of the insert. The AF5 chip breaker geometry has uneven chipbreaker grooves, with a shallower groove on the outside cutting corner and deeper groove toward the inside cutting corner. This enables a very efficient chipbreaking operation and a smooth, scratch-free finished workpiece surface. The Walter Cut G1111-P grooving holder has a diameter range of 2.362 to 19.685″ (60-500 mm).

Related Content

-

Repeatability and Rigidity Are Key for Quick-Change Swiss Tooling

A rotary wedge clamping system is said to enable this two-piece, modular tooling system for Swiss-types to offer the performance of a solid tool.

-

Data Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

-

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.