Walter Turning Grades Feature Curved Wiper Cutting Edge

The FW4 and MW4 positive wiper geometries provide a wiper action that can reportedly be used to reduce machining time by using double the feed rate.

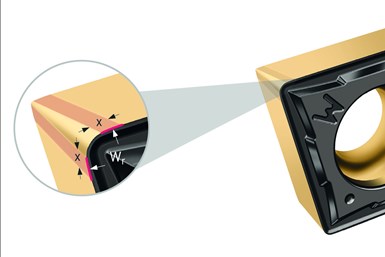

Walter’s FW4 and MW4 positive wiper geometries are designed for longitudinal turning and facing. They combine a “wiper effect” and the wear-resistant Walter Tigertec Gold grades.

The curved wiper cutting edge makes the wiper action universal across various material groups, such as steels, stainless steels, cast irons or even super alloys. It is said the wiper action can be used to reduce machining time by using double the feed rate, while imparting the same surface finish. According to Walter, feed rate increases of up to 300% were successfully utilized, in some cases.

The FW4 universal wiper geometry with a narrow chipbreaker, which generates short chips, is for finishing operations. The machining parameters for the FW4 geometry are a feed of 0.0012"-0.020" and a cutting depth of 0.004"-0.100". The primary application is turning steel, stainless steel and cast iron (ISO P, M and K workpiece groups), while the secondary application is turning super alloys (ISO S workpiece group).

The MW4 universal wiper geometry features an open chipbreaker groove and longer radius wiper cutting edge for high feeds in medium machining. The machining parameters for the MW4 geometry are feeds of 0.005"-0.022" and a cutting depth of 0.020"-0.180". The primary application is turning steel and cast iron (ISO P and K workpiece groups), and the secondary application is turning stainless steel and super alloys (ISO M and S workpiece groups).

Because of the wiper edge’s curved design, improved surface quality, productivity and process reliability are achieved even when the machine tool is not aligned 100% precisely, such as if the turret is slightly offset. The new chipbreakers also increase the chipbreaking range, resulting in less machine downtime caused by the creation of bird nests.

Related Content

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

The Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

-

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

.png;maxWidth=300;quality=90)