Autodesk Tour - Spring 2014

After its acquisition of Delcam in February, I thought perhaps Autodesk may have a lull in big news announcements. But last week I had the opportunity to visit the company’s facilities in San Francisco, and there’s still a lot to say!

After its acquisition of Delcam in February, I thought perhaps Autodesk may have a lull in big news announcements. But last week I had the opportunity to visit the company’s facilities in San Francisco, and there’s still a lot to say!

During the first couple of hours of my tour on Tuesday morning, I saw the company’s One Market Street Gallery, which features regularly changing exhibits of an assortment of design wonders in which one or more Autodesk products was used. The displays range from architectural and construction designs, such as models of the Shanghai Tower and the Bay Bridge, to media and entertainment work, such as the computer-generated imagery created for the movie Avatar, to the 3D digital prototypes used for large Legoland models.

Later in the morning, we walked a couple of blocks to the company’s new Pier 9 facility (opened in the fall of 2013), which extends out onto the San Francisco Bay. This remarkable 27,000 square foot workshop includes a digital fabrication lab, a woodworking shop, a metalworking shop, a 3D printing lab, laser cutting and printing capabilities, an electronics workshop, a commercial test kitchen, and an industrial sewing center, as well as smaller specialty project areas. The facility is intended to provide hands-on experience to further the understanding of the interface between software and hardware. It allows employees and artists-in-residence to showcase the company’s products by pushing the boundaries of the software and hardware.

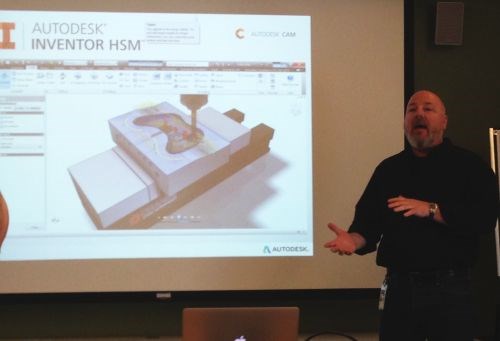

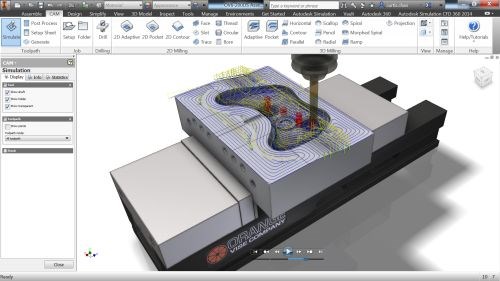

While at Pier 9, Carl White, senior director of manufacturing engineering at Autodesk, and Anthony Graves, CAM product manager, announced the commercial availability of Inventor HSM, an integrated CAM solution for Inventor users. Inventor HSM 2015 helps machinists, designers and engineers turn their Inventor designs into manufacturable parts by generating machining toolpaths directly in the software. “Inventor HSM will help users manufacture high quality finished parts, while saving valuable time and resources,” says Mr. White.

This slideshow of my visit provides a clearer picture of the many things Autodesk is doing to boost creativity in a number of industries.

.png;maxWidth=300;quality=90)