Turn-Mill Machining

A CNC turn-mill is a machine tool that resembles a horizontal or vertical lathe, but can perform milling, drilling, tapping and other operations using one or more milling spindles. A turning center having a turret with live tooling spindles in some of its stations is a simple example of a turn-mill. More sophisticated turn-mills have powerful B-axis milling spindles that can be oriented at a range of angles to machine complex geometries. Turn-mills offer the advantage of machining parts complete instead of running parts on multiple machines, especially those that offer a subspindle to enable backworking operations. Like a conventional turning center, bar feeders are commonly used to automatically supply bar stock to a turn-mill’s workzone to enable unattended or lights-out machining.

Latest Turn-Mills Articles

VIEW ALLPrecision Machining Technology Review: September 2024

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more.

Read MoreExpand Machinery Mill-Turn Enables Flexible Turning Performance

IMTS 2024: The Gen Turn CW 42MY is a small footprint eight-axis mill-turn lathe with a full-sized counter spindle.

Read MoreDigitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

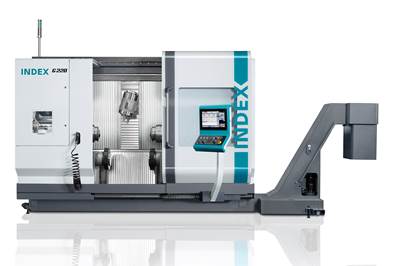

Read MoreIndex Corp. Turnkey Solutions Provide Flexible Manufacturing Performance

IMTS 2024: Index's C200 FANUC features powerful twin spindles that achieve rapid material removal.

Read MoreA Mill-Turn’s Value for Machining Micro Gears

This leading manufacturer of non-lubricated robotic gears uses a seven-axis turn-mill to machine components from “amorphous” metals such as bulk metallic glasses.

Read More5-Axis Machining Centers Transform Medical Swiss Shop

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth. (Includes video.)

WatchLatest Products

Grob Mill-Turn Machining Center Provides Flexible Performance

The G550T mill-turn universal machining center offers optimized milling and turning performance for a broad range of part materials in one setup.

Read MoreCompact Micro Turn-Mill for Small Precision Parts

PMTS 2023: The Spinner PD-CNC lathe can achieve high levels of precision due to its high-precision spindles, pneumatic clamping cylinders with programmable clamping force, ultraprecise ball screws, and hardened and ground sliding vibration-damping guideways.

Read MoreNakamura-Tome SC-100X2 Offers Superimposed Machining for Swiss-Type Parts

PMTS 2023: Superimposed machining from Methods Machine Tools’ multitasking machine lets shops take on complex contracts and more jobs compared to other machining methods.

Read MoreQuicktech T8 Hybrid Mill-Turn Center for Complex Milling

It is said the power, precision and versatility of the mill-turn center enables it to totally machine an extensive range of complex part sizes, contours and configurations.

Read MoreIndex's G220 Turn-Mill for Flexible Cutting

IMTS 22: Index’s G220 turn-mill center is said to produce a wide variety of parts in a single setup.

Read MoreStarrag’s Bumotec 191 Neo Turn-Mill Reduces Tool Change Time

The company says the 191 Neo turn-mill can also be used for grinding, polishing, skiving, gear hobbing and diamond cutting with no setup or fixture changes.

Read MoreFeatured Posts

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

Read MoreKeeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreA German Machine Tool Builder’s “Second Push” Into the U.S. Market

Spinner recently has taken strides to boost its presence, service and support in the United States as well as Canada and Mexico for its multifunction CNC lathes and milling machines.

WatchVideo Tech Brief: Live-Tool, Y-Axis CNC Lathe with a Compact Footprint

This small footprint, big-bore lathe offers a generous work envelope. The addition of Y-axis and live tooling enables milling, drilling and tapping for increased machine capabilities.

WatchVideo Tech Brief: Twin-Turret, Twin-Spindle Lathe Machining

This machine model features roller linear ways to accommodate low-frequency vibration technology to minimize chip size.

WatchThe Control’s Role in Machining Complex Parts

This company that produces medical implants finds value in the CNC for its turn-mill equipment that helps speed setups and simplify programming when producing intricate parts complete.

Read MoreTurn-Mills Supplier Categories

- CNC Software, Stand-alone

- Programmable Logic Controls (PLC)

- Communications Networks & Data Transmission Equipment

- Identification Systems

- Direct or Distributive Numerical Control (DNC) Systems

- CNC Units

- Digital Readout (DRO) Units

- CNC Turn/Mill Machines

- Digitizing/Scanning Systems

- Memory Units

- Robot Controllers

- Machine Monitoring

.jpg;maxWidth=300;quality=90)