Bar Puller Features Self-Adjustment

The EZ-Puller, from Accudyne Corp., addresses a series of bar puller concerns with its own approach to pulling barstock.

A few popular styles of bar pullers are available on the market today. All of these tools use some method of force to engage gripping members (grippers) on the end of a bar. Some of these tools bring the grippers in contact with the material while moving in the X axis; others move the tool into position to engage the work from the Z axis. Either way, the bar must project beyond the front face of the collet or chuck far enough for the grippers to hold on to the material. Once the tool has a solid hold on the material, the collet is opened and the pulling routine of the program is initiated.

A few important questions should be asked prior to purchasing a bar puller:

- Ease of setup: How quickly and accurately can the bar puller be adjusted from one size bar to another?

- Reliability: How well does the tool perform on an ongoing basis? Is there a need for recurring alignment or tightening of components?

- Repeatability: Are the pulls the same length every time?

- Versatility: Will the tool pull a variety of shapes, such as octagonal, hex and square stock, without spindle orientation M19?

- Speed of operation: How quickly does the tool operate? Does the tool need to pause before and after pulling?

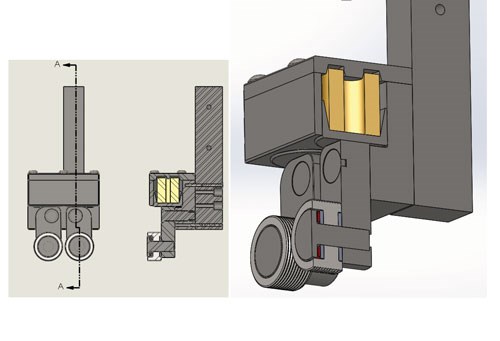

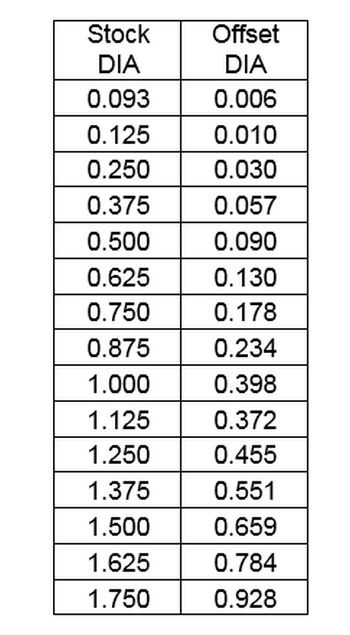

The EZ-Puller, from Accudyne Corp., addresses all of these issues with its own approach to pulling barstock. This tool uses hardened circular grippers that are attached to the end of two spring-loaded movable arms. These arms have a cam lobe built into their top end and pivot outward as the grippers advance around the bar on the X axis. As the arms pivot, the cam lobes compress urethane springs within the alloy steel body of the tool through means of a hardened steel lifter, much like the cam, lifter and spring arrangement in an automobile engine (see Figure 1). This design allows for the gripping of different size bars by changing the X value for the first X move in the bar-pulling part of the program (see Figure 2).

Because of the constant force of the grippers on the material, hex, square and octagonal stock can be can be pulled without spindle orientation (M19). The grippers are made of wear resistant, tool steel hardened to 58-60 Rc. These circular grippers have a buttress thread form that allows optimal pulling while leaving minimal marking of the bar end. The grippers have a close pitch serration that permits stock engagements of 0.16 inch on most materials and as little as 0.04 inch on some softer materials. The friction loaded grippers do not rotate while in operation, however, they can be manually turned to bring up a fresh surface if there is any sign of wear.

Polyurethane springs of 95A durometer are contained within the tool body and provide the force for gripping. These springs can be swapped out with softer (80A durometer) springs if working with delicate materials or thin wall tubing. According to the manufacturer, the robust design of the tool coupled with the unique form of the serrated grippers allows for rapid operation (up to 400 ipm) and extreme repeatability.

The EZ-Puller has an operating range of 0.093 inch to 1.750 inch in round stock, 0.125 inch to 1.625 inch in octagonal stock, 0.125 inch to 1.375 inch hex stock, and 0.125 inch to 1.00 inch in square stock. Mounting options are 0.750 inch square shank, 1.000 inch square shank, 1.000 inch round shank, and 1.000 inch round low-profile for machines with clearance issues. All wear parts are hardened tool steel.

Related Content

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreData Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

Read MoreParting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)