Tool Lifecycle Management concerns the entirety of the production process from the definition of tools through their use in planning up to the seamless transfer and use on the shop floor. The advantages of Tool Lifecycle Management are obvious: Throughout all departments, every employee should have access to tool data.

In order for this process to run smoothly, it needs a center in which all information converges—the TDM Base Module and an efficient database. Together they form the basis for tool management and enable economical and transparent data organization in all company divisions.

Every department has a different demand for tool data. For NC programming, it is the data of tool assemblies. In the tool crib, it is the ordering of information that includes tool items.

In turn, tool assembly requires tool lists, tool assembly information and workpiece setting sheets. The TDM Base Module depicts this basic structure of machining production on three functional levels.

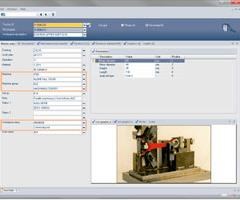

For every area represented on the software side, extensive data and documents about the tool can be filed. These data include feeds and speeds, which define conditions of use specific to materials and cutting grades. These records also include collision parameters and presetting data for tool assemblies.

Linking tool items, tool assemblies and tool lists is also of central importance: The user can always see which items are built where and where they are located on the tool lists.

The tool management software also provides important information for the tool crib, including the location of tool items at workspaces, the management of parts in need of repair, as well as the minimum stock level.

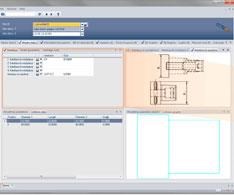

The Base Module meets all the requirements of modern, digital production: tool selection via graphic class or the features of technology and machining procedures; automatic tool assembly with plausibility check; the integrated CAD kernel for displaying 2D and 3D graphics; the automatically generated parts, tool and production lists; and the automatically generated discrepancy lists or the tool catalogs of more than 50 tool manufacturers that can be integrated. These characteristics all provide a solid basis for the Tool Lifecycle Management of the future.

Structural and Base Data

The Base Module offers a basic configuration of predefined base data to describe tools and their use in detail. The following information (with screen shots) is stored in TDM by default.

Making chips is how shops make their money, and it takes tools to make chips. Automating tool management can help streamline efficiency and reduce waste by applying these critical components.

Related Content

-

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

-

Shop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

-

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)