When Mitch Looper founded M2C Racing in 1990, it was a small shop that produced high-quality parts for remote control (RC) vehicles. Neither he nor his son, Avery, now company owner, knew that in a quarter of a century, it would become one of the largest RC aftermarket parts manufacturers in the world.

Avery Looper was present for the creation of M2C in Edgemoor, South Carolina, but eventually moved to California to work in aerospace manufacturing for the next 30 years. While he was gone, his father ran M2C as a hobby shop. However, the company quickly prospered once it got into the off-road “bashing” side of RC racing a few years ago. Instead of racing around a track or with defined rules, “bashers” test the limits of their vehicles by jumping them as high or as far as possible, which can put a strain on the vehicles. M2C tests the strength of the parts it manufactures by doing the bashing itself. If its parts hold up during a bashing session, it is safe to determine the quality of its workmanship is high.

Its shop now has 10 employees who run equipment including five VMCs, one HMC, two drilling and tapping machines and, most recently two Swiss-type lathes. Looper decided to purchase the shop’s first Swiss-type to manufacture its own RC vehicle driveshafts, despite having no experience with CNC sliding headstock machines. The company had been contracting out all its Swiss-type machining work when it experienced growth and needed to increase the number of parts produced. Its Swiss work was a growing portion of its product line, which included about 10 different high-production parts such as driveshafts, specialty screws and pins. Although he had never even

Avery Looper (left) and his father, Mitch Looper, run M2C Racing, a remote control aftermarket parts manufacturer. Recently, the company purchased two Star CNC Swiss-type machines to bring its Swiss work in-house. Photo Credits: M2C Racing

seen a Swiss-type before, Looper realized that farming out this work was posing a financial and creative block. The time had come to learn how to do Swiss machining on his own and purchase the necessary equipment for the job.

After researching a few different options, Looper settled on an SR-38 Type B 10-Axis Swiss-type from Star CNC. “We looked at a standard machine first, but then I saw one with a B axis and I couldn’t turn it down,” he says. “The upgrade has been incredibly worth it.”

Now that he had chosen a Swiss-type machine, finding CAD/CAM software that was relatively easy to use for programming that machine was important. The company initially chose a software that Looper’s father thought was a safe choice because he had used it for most of his career. However, there was a 12-week delivery delay with the postprocessor and, when it did arrive, it failed. This spurred the shop to look for an alternative software to get the most out of this new and unfamiliar machine tool platform.

Simple Programming and Solid Support

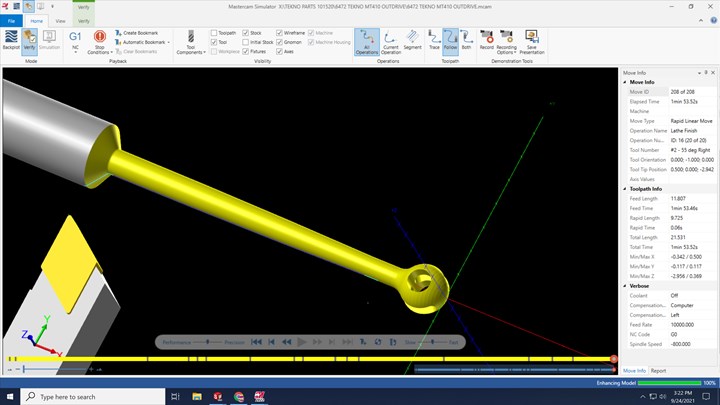

Star CNC machine purchases come with an on-site training package to familiarize users with the machine. The machine tool builder’s representative who visited M2C, Milton Palma, used CNC Software Inc.’s Mastercam CAD/CAM Swiss product to demonstrate machining, and Looper was relieved by its simplicity. Having used the same CAD/CAM software for the entirety of his career in aerospace manufacturing, he was already comfortable with the interface and confident with the system’s abilities.

On the first day of training, Looper reached out to Chris Leclerc, Swiss product specialist at CNC Software. Leclerc not only sent working programs for Looper’s parts that same day but he hosted one-on-one webcam training to help Looper learn the nuances of the product.

“The code output is exactly how I want it,” Looper says. “It’s perfect because I don’t believe in doing manual editing which could produce bad parts or cause crashes and other problems.”

Brian Kadow, president and applications engineer of certified Mastercam reseller CAD/CAM Solutions Inc. (Snellville, Georgia), installed the system for M2C Racing. In fact, as an RC enthusiast himself, Kadow is always thrilled to lend not only his software expertise but his opinions on RC ideas. He even helped Looper develop the M2C 7160 Servo Saver for Losi race cars, a steering arm made from 7075 T6 aluminum.

To fine-tune M2C’s output code, Kadow and Leclerc brought in Tim Scott from Mastercam partner Postability Inc., a developer of NC postprocessors. With his expertise, the company now has the postprocessor dialed in to the point where the shop does not have to touch the programs at all.

“The code is output exactly how I want it,” Looper says. “It’s perfect because I don’t believe in doing manual editing which could produce bad parts or cause crashes and other problems.” Knowing that his code will run correctly and save those edits automatically gave Looper the confidence to run his Swiss-type with entry-level operators and little supervision. Every G and M code or variable value that he was unfamiliar with is labeled with a helpful comment, he explains. And, when he calls CNC Software, the issue is always solved that same day.

Having used the same CAD/CAM software for the entirety of his career in aerospace manufacturing, Avery Looper was already comfortable with the Mastercam interface and confident with the system’s abilities.

Helpful CAD/CAM Capabilities

M2C went from having zero production in its Swiss department to producing new parts on a weekly basis. Not only does it make the parts that it once outsourced but the company has been about to expand its product line since doing its Swiss-type machining in-house. Unlike many other users of Swiss-types, the shop produces short-run parts and an imposing number of prototypes. Lot sizes vary from 100 parts to 400 parts. The company sets up the now two Swiss-types for a new part on a weekly basis (sometimes up to three to four times a week) with changeovers using the same size material.

Looper says part of the company’s success relies on a CAD/CAM tool that Leclerc exposed him to — the POCO routine, or the pickoff/cutoff operations. With POCO, the user clicks the solid, and the software automatically generates the cutoff sequence with the second head coming in and picking it off.

“It’s all one click,” Looper explains. “After that, it will simultaneously run the backside operations in the subspindle while automatically machining the next part in the main spindle.”

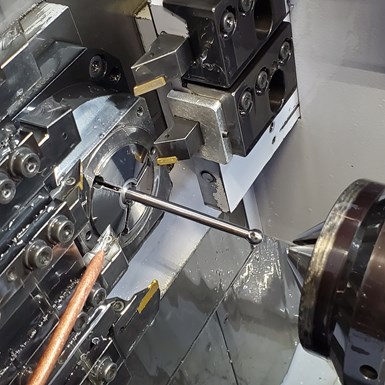

Swiss machining has completely changed how M2C is able to machine driveshafts, which are now a sizable portion of its sales. The driveshafts, machined from 4140 heat-treated steel, were designed by Looper.

Swiss machining has completely changed how M2C is able to machine driveshafts, which are now a sizable portion of its sales. The driveshafts, machined from 4140 heat-treated steel, were designed by Looper. He conducted the stress testing in SolidWorks first and then exported it to Mastercam for programming. After setting his parameters, he used the CAD/CAM software’s automatic Turn Profile function to extract machining geometry, which automatically provided all his turning profiles and drew his geometry.

Looper uses the Turn Profile button to generate lines and arcs for ease-of-use and total control of the tool path. He creates view sheets for each operation, which are level sets (layers) that he can turn off and on with one click, he explains. This function enables him to analyze different components within the part piece by piece without being overwhelmed working on the entire part all at once.

Pinch turning with the Swiss-type enables Looper to machine his driveshafts in only one operation and with only one setup. He explains that the part, which has almost no flat areas and can be as long as 8 inches, would have been difficult if not impossible to machine on a lathe profitably.

Looper then turns the front of the driveshaft and completes the five-axis drilling and milling on the constant velocity driveshaft feature in preparation for pinch turning. Next, the machine grabs the front of the part with the subspindle and pinch turns the rest of the part.

The operation removes half the material with the front tool and half the material with the rear tool, doubling part production output and extending tool life. Pinch turning with the Swiss-type enables Looper to machine his driveshafts in only one operation and with only one setup. He explains that the part, which has almost no flat areas and can be as long as 8 inches, would have been difficult if not impossible to machine on a lathe profitably. “And the Swiss-type enables us to produce a better, prettier part,” Looper adds.

Do Not Settle

Although the shop’s newfound Swiss-type machining abilities are exciting for Looper, he also appreciates and understands the value of quality customer service and how much it can change the competitiveness of a niche shop. He experienced how the customer service he received from Mastercam positively affected his operation — which, in one aspect, places him in his customer’s shoes.

His recommendation to other machine shops is not to settle for a supplier that can’t or won’t solve problems; there is always someone else who can and will. With his responsive, supportive group of expert representatives behind him, Looper says he can focus on maxing out the potential of his new Swiss-types and programming software. He says he has not yet explored how tight he can make tolerances because his system is more than meeting his expectations for parts with micron-level tolerances. However, he likes that it leaves room for improvement in the future.

“In just a couple months, I got to the point where I can machine almost anything that will fit on this machine,” Looper says.

CNC Software Inc. | mastercam.com

Star CNC | starcnc.com

M2C Racing | m2cracing.net

Related Content

Mastercam Software Improves Programming Flexibility

IMTS 2024: Mastercam introduces Mastercam 2025, with features including Mastercam Deburr for automated edge finishing, finish passes, mill-turn support for Y-axis turning and automatic license update notifications.

Read MoreCAM Software’s Place Serving Emerging Trends

SolidCAM aims to align its product development and customer engagement strategies to address the evolving needs and challenges of the manufacturing industry.

Read MoreWho Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.

Read MoreLone Shop Machinist Benefits From Five-Axis CAM Modules

This California shop owner applies five-axis strategies for more efficient milling of parts with challenging geometries, free-form surfaces and deep cavities.

Read MoreRead Next

Swiss-Type Turning Point

This northern Ohio shop recently added its first Swiss-type lathe to gain long stretches of unattended machining largely because its continuous efforts to find new operators for its more conventional equipment had proven to be unfruitful.

Read MoreThe Right (Machine) Tool for the Right Job

This high-production shop uses both mechanical and CNC Swiss machines to make parts, but which machine is right for which job?

Read MoreSwiss Shop Chooses CAM Over Hand Programming

This shop’s manual (by hand) CNC programming was slowing it down until it discovered a CAM software for Swiss-type lathes.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)