CNC Cutter Grinding In-House

As tooling complexity increases, one might expect in-house tool grinding to gradually fade away. In fact, though, more and more shops are taking advantage of CNC tool grinding’s increased capabilities to improve consistency, flexibility and productivity.

Share

Many factors have driven the rise of popularity of in-house tool grinding. The ability to financially justify the addition of a CNC tool grinder could be the biggest. Over time, the cost of CNC tool grinders has come down, particularly in relation to the number of features, the level of technology and the capabilities that are available. The ease of use of the software has also gotten much better, allowing a company that is not actually in the tool business to buy a tool grinding machine and support its own tooling needs. By manufacturing and/or resharpening its own tools, rather than relying on an outside source, a shop gets a firm grasp on control of its inventory, lead times and part quality.

Screw machine shops are no exception when it comes to trends toward increased use of in-house-generated tooling. These shops have a history of trying to maintain as much control as possible of all aspects of the business, including tooling requirements, but the limitations of manual tool grinding have often created obstacles to productivity advancements.

The complexity of the tooling has grown continually as screw machines have become more flexible and more expectations have been put on the demand for the complexity of parts that they are producing. Getting the necessary forms for the tools, along with quality performance from the tools to provide consistent parts, has steadily grown more challenging with manual grinders.

While the challenges of more difficult parts have raised some issues, the knowledge of grinder operation may be the bigger issue. Screw machine shops are seeing a general aging of the employee base, where operators have a great deal of experience in getting good tooling off of a manual machine. This knowledge of the touch and feel of producing a quality tool is not easily handed down to new employees in a short time frame. On the other hand, training on a CNC grinder—operating the controls and making sure the program is correct—is more straightforward and tends to suit the interest of more people who are new in the business.

Finding A Solution

ANCA, supplier of a range of CNC tool and cutter grinders to meet large-scale manufacturing and entry-level production requirements, is addressing the needs of the screw machine shop with a line of CNC grinders targeted specifically for this market.

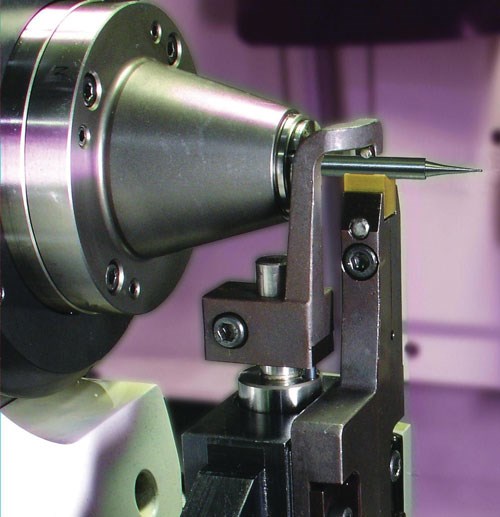

The RX7sp is a high-production machine for small parts (thus the “sp”). Specifically intended for grinding cutting tools with diameters as small as 0.02 inch (0.5 mm), the machine is designed to provide users the ability to expand their manufacturing and produce cutting tools for medical machining and other micro applications.

This micro tool grinder has a double-ended 3.5-kW HSK spindle that gives both face and taper contact on the arbor for improved wheel runout and positional accuracy. It also includes ANCA’s standard iBalance automatic wheel balancing system that is built into the CNC software. This feature helps to remove the harmonics and vibrations from the grinding wheel, enabling the grinding of much smaller-diameter tools without breakage.

For additional reduction of vibration and tool runout, an overhead support mechanism is included to support the tool during grinding. This system uses a clamp over the top of the tool to push the tool down into the V-block underneath, keeping it steady during the grinding process.

Supporting the grinding and workholding components is a rigid polymer concrete base. The work zone of the machine is fully enclosed to allow flooding of the area with high-pressure coolant. The machine has linear glass scales as opposed to rotary encoders for accurate positioning and precise machine movement. The high-accuracy movement provided by this positioning feedback system is particularly critical as the tooling gets smaller and more complex.

All Things Considered

And so, the implementation of a CNC tool grinder for in-house tool grinding could potentially help a shop satisfy its own increased tooling requirements. But return on investment (ROI) is still a concern, especially when comparing the costs of a manual grinder with that of a CNC grinder that could be ten times more expensive.

Through studies and consultation with customers, ANCA has established a benchmark for adding a CNC tool grinder to a shop. Russell Riddiford, president, says, “If you have six or more screw machines or machining centers, you can justify a CNC tool grinder. Less than that could work, but the ROI will be longer, and most customers are looking for a ROI of 3 years or better.”

Part of the psychology involved is in understanding the indirect financial benefits. Russell explains, “As a support machine rather than a production machine—it is not putting parts in the customers’ hands and, thus, not making a direct profit—the grinder sees even more emphasis on ROI. Shop owners might see parts rolling off of a dozen screw machines and want to add even more. But when it comes to buying a machine to support those, they hesitate because the benefits aren’t as obvious.”

The bottom line is that a decision must be made regarding costs, both seen and unseen, related to relying on an outside source for tooling needs. Leaving it to the experts can guarantee that a shop will have quality tools while allowing it to focus on its core business. However, the shop is then under the constraints of the experts’ schedule and pricing. An in-house CNC tool grinder might give a shop the quality tools it needs while providing the consistency, tool design, flexibility and quick turnaround necessary for making new parts to meet increased productivity requirements.

Related Content

The Advantages of Turning and Grinding on One Machine Platform

Instead of using a dedicated grinding machine or an outside grinding vendor to achieve very high surface finishes, a machine that can hard turn and grind can reduce WIP and speed part completion while taking up minimal floor space.

Read MoreAutomation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

Read MoreWhat is CNC Peel Grinding?

It resembles single-point turning on a lathe because, similar to a lathe’s tool, the grinding wheel moves in the X and Z axes to grind contours, diameters and other features.

Read MoreGrindstar Replaces Turning With Efficient Grinding

PMTS 2023: The Grindstar machine uses a method that enables the entire workpiece contour to be ground in a single processing operation.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More