Collateral Benefits of Ultrasonic Cleaning

A manufacturer of traffic and crosswalk signals strives for part durability and consistency throughout its operations.

Part durability and consistency are key objectives for manufacturers of traffic and crosswalk signals and other technology that must stand the test of time in the elements. One such company is meeting these demanding requirements with its products while also realizing cost savings and decreasing its environmental impact.

The July issue of Production Machining introduced readers to Campbell Company (Boise, Idaho), who designs, engineers, and manufactures products for the traffic industry—most significantly, accessible pedestrian signals (APS), push buttons and pedestrian stations for intersection crosswalks. The products must be resilient and efficient in all climates and conditions, even if exposed to chemicals or other substances that typically result in corrosion, scratches or other damage.

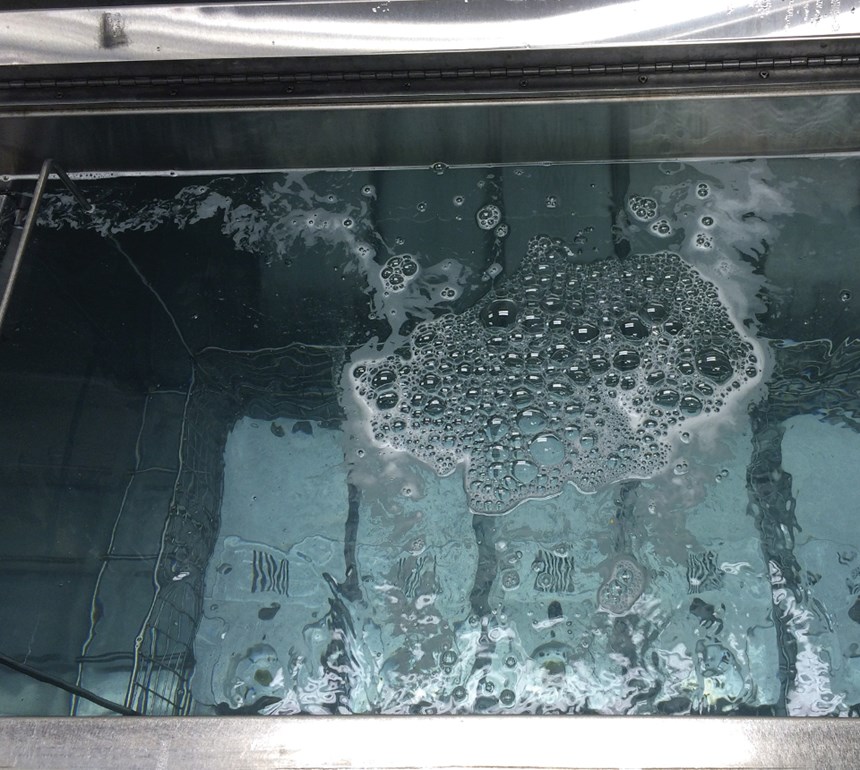

July’s article, “Flexible Automation on a VMC,” focused on the automation system that Campbell Company has implemented to significantly improve its production for push button housing components. The company also sees production advantages in its finishing operations through the use of ultrasonic cleaning.

To ensure the durability of the APS components and other related parts, Campbell Company uses powder coating, which can provide a finish 100 times more durable than paint. During the powder coating process, technicians spray a fine powder onto components and heat it until it adheres to the metal. For the powder to adhere properly, the metal must be meticulously cleaned prior to spraying, which also helps to prevent corrosion of the metal beneath the coating.

For years, the company had cleaned components using time-consuming scrubbing with brushes, warm water and a soap solution, or tumble washing, which almost always left residue. “Hand cleaning was a slow, tedious process, and results were inconsistent, to say the least,” says Clark Hill, production supervisor for Campbell Company. “Human hands and brushes can’t get into all the tiny crevices and get the results we require. The powder coating process is core to our business. We needed to find a different way to get those components as clean as possible every time.”

Mr. Hill was familiar with ultrasonic cleaning technology through a previous employer. When he started at Campbell Company, he knew this technology could provide the required level of cleaning, so he looked around for an industry leader who was reliable, dependable and U.S.-based. An online search led him to Omegasonics, headquartered in Simi Valley, California.

“Omegasonics came up with a fair price for a high quality product,” Mr. Hill says. “They were responsive, friendly and explained the technology and their machines very well. But they also had the best product for my budget. Besides, I thought, if NASA uses them, they must be good enough for us.”

Higher Productivity, Lower Environmental Impact

Mr. Hill reports that Campbell Company’s productivity has increased 36 percent since it started using a 5038i ultrasonic cleaner from Omegasonics in December 2014. He attributes the increase to faster and better cleaning results, lower costs associated with the process and increased employee morale.

Previously, hand scrubbing of simpler parts, such as the housing for a crosswalk call button, took approximately one minute per part. With the ultrasonic machine, technicians can clean 40-50 parts in four minutes. More complicated parts, such as the housing for an APS, used to take four minutes to clean by hand. Now the company can clean five housings at a time, and it only takes three minutes.

Cleaning results are much improved, too. Microscopic crevices and pores in the components are meticulously cleaned, making the powder coating process more effective and ensuring consistent production results.

Campbell Company uses a fraction of the cleaning solution they once used. Hand scrubbing required gallons of degreaser each week. Now they use approximately half a gallon of Omegasonics’ OmegaClean (which is comparable in price per gallon) every two weeks. Mr. Hill sees this as a cost efficiency benefit, but also appreciates the company’s reduced impact on the environment.

Happy Employees Equal Better Outcomes

Mr. Hill believes one of the greatest benefits ultrasonic cleaning technology offers is increased employee morale. “Our people are our No. 1 asset,” he says. “Hours of hand scrubbing doesn’t really help keep morale up. The technology makes our technicians’ jobs easier and faster, and they are able to produce a superior product every time. Since we bought the ultrasonic machine, our people are happier, and we’ve seen greater outputs.”

The company currently is looking into using its machine to create additional process efficiencies. It recently began building the signals’ circuitry in-house and likely will begin using the technology to clean circuit board screens, which contain many tiny holes that are easily clogged during manufacturing.

“We are always looking for ways to improve what we do,” Mr. Hill says. “With ultrasonic cleaning, we have peace of mind that we are putting out a better quality product and that our customers can trust that.”

Related Content

Multisolvent 100 Vacuum Vapor Degreaser Provides Contactless Cleaning

PMTS 2023: With applications in the most demanding industrial sectors, the machine is especially useful for cleaning parts in the turning, precision mechanics, medical and aerospace industries.

Read MoreOvercoming 3 Common Challenges With Automated Particle Counting

Facing difficulties while performing particle analysis is normal but should not be discouraging. Here are some ways to handle the most prevalent issues that can arise.

Read MoreIn-line Monitoring for Automated Immersion Cleaning Systems

Ecoclean’s Acoustic Performance Measurement (APM) system provides in-line measurement of ultrasonic frequency and power in fully automated immersion cleaning systems on a batch-by-batch basis or at defined time intervals, such as once a shift, day or week.

Read MoreEnvironmentally Friendly Model 550 Versatile Parts Washer

PMTS 2023: This washer is useful in a variety of applications, including tool rooms, maintenance operations, low production and precision cleaning.

Read MoreRead Next

Flexible Automation on a VMC

Robot loading and unloading of the workholding that is used in the machining center facilitates the ability to change jobs during an unattended run.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)