Customizing Collaborative Robots with 3D Printing

A company that helps manufacturing companies implement collaborative robots has found that additive manufacturing can produce custom parts for these systems faster and cheaper than machining.

Many shops are opting to automate manufacturing operations with collaborative robots. These systems are flexible, safe and relatively easy to implement. However, collaborative robot arms often require custom parts, like end effectors that enable them perform tasks like CNC machine tending, automated part sanding and brake press machine tending. CNC machining is not always a good option for producing these parts because of its long lead times and high costs, so companies are looking for alternative methods of part production.

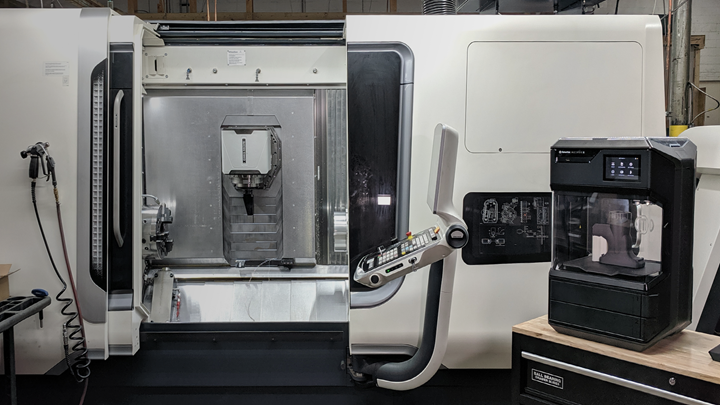

All Axis is a machine shop and integrator that helps other companies automate machine tending with cobots like the one seen here.

One shop facing this issue was All Axis Robotics, a Dallas, Texas-based machine shop and integrator that helps other machine shops and manufacturing facilities develop and implement automation systems for machine tending. Customers enlist the expertise of the company’s mechanical and manufacturing engineers to streamline their manufacturing operations with robotic arms and custom end effectors.

[Related: An Ohio manufacturer of shock absorbers with 33 cobots relies on 3D printing capability to equip all this automation to perform effectively. Here is how 3D printing and collaborative robots go together for Thyssenkrupp Bilstein (includes video).]

“One of the challenges we faced when adapting our collaborative robots and automation in the machine shop was the need to develop custom parts during the process,” says Gary Kuzmin, CEO of All Axis Robotics, a machine shop and integrator. “We would have to develop custom brackets, fixtures, or fingers for the grippers, and not all of this would be possible to produce on CNC machines.”

3D printing addresses many of the issues the company has with CNC machining custom parts—it can produce specialized parts quickly and inexpensively. So, the company decided to buy a Method X 3D printer from MakerBot. “When we purchased the MakerBot Method, we automatically obtained all that capability for customizing all these different parts. Within days, we were able to print custom parts for our machines,” Mr. Kuzmin says. “The relevance of having this machine within our process is that we have a quick turnaround capability to produce custom parts that we can integrate into our systems immediately.”

All Axis often needs to produce custom end effectors to go on its clients’ cobots. Machining these parts can be costly and time-consuming, so the company has opted to produce many of these parts on a Makerbot Method 3D printer.

The engineering team at All Axis uses 3D printing to produce custom tooling parts, reducing lead times from months to hours for their bespoke robot end-effector designs. This ability to create custom solutions for customers, combined with rapid turnaround times, has helped All Axis gain a competitive advantage against competitors as more manufacturing facilities upgrade new and legacy equipment to meet the increasing demands of industry 4.0 and the modern global marketplace.

“Not only was it extremely valuable for us to make on-demand custom parts for what we needed to keep our operations going, but we were able to implement 3D printing for our customers and their needs,” added Kuzmin. “As our engineers realized the capabilities of 3D printing, we were able to create a product line of 3D printed parts for existing customers who had similar challenges.”

For example, All Axis engineers designed and manufactured a custom part sander using MakerBot’s real ABS material with the Method X. The robot sander automates time-consuming manual aluminum sanding operations, helping a machine shop to run more efficiently by freeing up personnel for other tasks. It features two sides with different grid sand pads as well as a connection for a vacuum to remove debris.

By approaching the part design through the lens of freeform additive manufacturing, All Axis engineers we able to 3D model the part quickly without having to account for complex assembly considerations typical of traditional manufacturing processes.

By producing the part with an in-house Method printer, the team was able to eliminate undesirable factors typical of traditional manufacturing processes, including expensive machinist time and material costs. And by approaching the part design through the lens of freeform additive manufacturing, the engineers were able to 3D model the part quickly without having to account for complex assembly considerations typical of traditional manufacturing processes.

The ability to print with Stratasys SR-30 soluble support material allowed the engineers to design the sander as one complex part, which would’ve been impossible to machine using traditional manufacturing methods. Method’s dimensional accuracy ensured that the part mated perfectly with the robot arm on the first try. The use of production-grade ABS printed in the 100°C heated chamber produced a very strong and durable tool capable of withstanding the harsh machine shop environment.

“All Axis Robotics is a prime example of a customer who has embraced the possibilities of additive manufacturing to remain competitive in today’s environment,” says Nadav Goshen, CEO of MakerBot. “By investing in in-house 3D printing solutions, companies like All Axis can change how they approach manufacturing. By combining automation with the quick part turnaround time Method has to offer, companies can now improve their production capabilities and grow business opportunities.”

“One of the interesting things about our shop is that right next to our million-dollar machines on the production floor is a MakerBot Method, which is about $6,500. And it’s that $6,500 machine that is able to keep our million-dollar machines running automation,” Mr. Kuzmin notes.

Related Content

Unattended Production Takes More Than the Most Capable CNC Machine

Process planning and reliable peripherals are key to successful lights-out manufacturing.

Read MoreAutomation Idea for Halloween?

Maybe not. But, the candy-throwing robots at MetalQuest’s Nebraska facility do enable the contract machine shop to stand out at career fairs and similar events.

Read MoreHigh-Volume Machine Shop Automates Secondary Ops

An Ohio contract shop added a compact, self-loading CNC lathe to perform unattended secondary ops on a part for a key customer rather than running it on a manually loaded chucker.

Read MoreZoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)