Faster Change-Overs Allow Focus On Machining

A creative Midwestern shop shows that its productivity edge runs all the way down to its relationships with vendor partners. With the right clamping and centering device, the company has been able to reduce workpiece change-over times by as much as 50 percent while improving rigidity and precision.

A company in northeast Indiana, in the heart of America’s industrial Midwest, is known for the uncommon, the out of the ordinary and the non-traditional. The company—C & A Tool, located in Churubusco, Ind.—is headquartered in a facility with a distinctive Alpine look, complete with landscaped ponds in its front yard, half-timbered walls and fish-scale shingles on the roof. This setting is the company’s way of bringing an element of old-world craftsmanship to today’s industrial technology. Since the company opened its doors in 1969 as a mold shop, it has successfully flourished into a team of more than 500 employees.

The company began as a small tool and die maker in a garage and since has become a national and international supplier of metalworking specialties. “We evolved into one of the premier tooling and precision, contract, advanced manufacturing companies, working in the diesel fuel systems, medical, aerospace and industrial markets,” says Gary Sroufe, the “go-to guy” for the multi-spindle area.

When asked what his job title is, Mr. Sroufe says, “We really don’t have titles here, only empowered technicians and specialists that make up self-directed work teams, working three shifts, as needed, to meet our customers’ highest-precision needs. In fact we don’t have time clocks or rules; we strive to maintain a good understanding of the customers’ needs and work to get the job done. If employees enjoy where they work, and respect the trade, they will help the company reach its goals of exceeding customer satisfaction and service levels, as well as make it more productive. By trade, we are tool makers, engineers, metallurgists, quality control specialists and machine specialists dedicated to achieving the uncommon for the customer and our industry.” With the continued growth of C & A Tool, many new hires become second-generation employees.

Providing solutions for customers is an everyday challenge, and when it comes to tooling or the products that can be produced from fine tooling, few companies can offer what C & A Tool can in capability and end results. According to Mr. Sroufe, “These are the results customers expect in the form of finished products for high performance transportation, business and industrial equipment, for absolute precision of medical and surgical applications and for use in many other industries.”

Flexibility, Capability, Expandability

With multiple locations and specialized production facilities, C & A Tool’s “pod” concept represents the latest in ergonomically designed and expandable manufacturing capability. The company’s new South Building, for example, is shaped like an “H”—191,157 square feet on 46 acres, with each leg containing four pods of 20,000-plus square feet. The cross arm is the central service corridor. It is 24 feet wide, serving each pod and permitting materials and parts requiring several operations to move easily from pod to pod. Corners of walls are cut off to permit lift trucks to turn more easily. Each pod is dedicated to a metalworking specialty, with labels such as Metal Prep, Lathe, Mill, Grind, Deburr and Assembly.

Quality Assurance

With adherence to the highest national and international quality, manufacturing standards are part of every operation at C & A Tool. In other words, quality is ongoing and an integral part of the manufacturing process. With multiple certifications to support multiple industries, each production facility, each production process and each production operation meets the stringent standards for highest quality set by these organizations. Further, the facilities and operations also meet FDA standards and approval for manufacturing in the sensitive areas of medical, surgical, pharmaceutical, food and hygiene. The company’s certifications include ISO/TS 16949:2002 - Second Edition, ISO9000_AS9100.

Teamwork And Partnership

At this shop, teamwork is paramount to achieving goals. This teamwork includes solid relationships and communication among employees, customers and vendor partners. One of these partners is Hainbuch America Workholding Technology.

Manufacturing is a very intricate process, and C & A Tool recognizes Hainbuch for its strategies to invest in the latest technologies for product quality. Both companies are continuously involved in research and development as they pursue answers to their customers’ challenges.

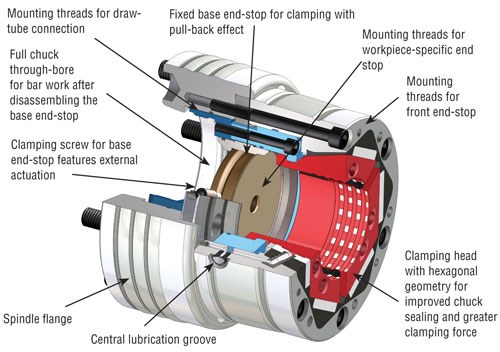

Most machines are typically outfitted with a factory standard workholding component. While acceptable, Mr. Sroufe does not believe the factory standard unit can always provide the most flexible, accurate or efficient solution for his company’s applications. One of the most significant yet overlooked opportunities in which manufacturers can gain the competitive edge is by means of improved workholding solutions. The proper clamping and centering device can minimize workpiece change-over times by as much as 50 percent while improving rigidity and precision, therefore increasing the value of machines and profitability, according to Hainbuch.

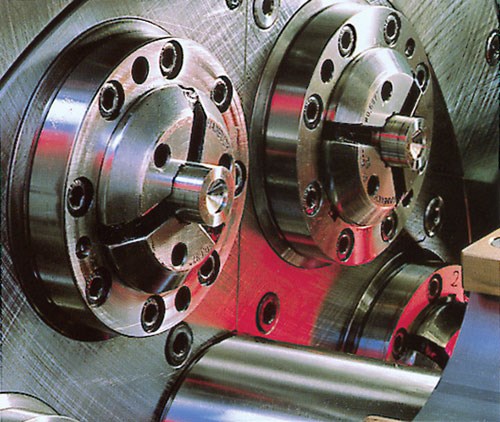

C & A Tool combines its line of metalworking equipment from companies such as Mori Seiki, Index, Star CNC, Kellenberger and Voumard with a talented group of operator/programmers. This approach to metalworking, combined with proper workholding, results in controlled processes even in high-precision applications. An example of this is in the Index multi-spindle area, where C & A Tool uses about 50,000 pounds of steel barstock a week to produce more than 5 million parts annually.

“Using the Hainbuch chucks, quick-change collets and accessories in our machines allows us to concentrate on machining, not change-overs,” says Mr. Sroufe. “The ability to change the size of the collets in the machine in only a few minutes is critical in our fast-paced environment. Setup times on multi-spindles are sometimes dictated by the time it takes to change collets. With Hainbuch collets in the machine, collet change times are not figured into the equation.” Mr. Sroufe also says specs on parts that the company runs in its six-spindle Index machines are much tighter than most would expect for this type of machine. “We have several parts with a 0.00025-inch tolerance. Without these high-precision collets, we would not be able to hold such tolerances,” he adds.

Another important aspect of running precision parts is keeping the collets clean. The barstock is cleaned before it goes into the machine; however, the collets still require some maintenance to reach the company’s expectations of added machine and tool life.

“The easier it is to clean them, the more often it will get done,” says Mr. Sroufe. “With the Hainbuch collets, we can pull all six of them, clean them and be back up and running in less than 10 minutes. Hainbuch products have been instrumental in helping us to streamline our workholding needs.”

Pure Proficiency

C & A Tool has come a long way since its start almost 40 years ago. As part of its long line of machining capabilities, including milling, EDM and grinding, the shop features extensive turning operations. It has multiple live tool CNC lathes with two-axis and four-axis turning capabilities, Swiss-turn bar feed operations, hard turning capability and multi-spindle cam and CNC turning. Superior, uniform, known stock conditions are stringently maintained by the metal prep division pod, which opens directly into the turning and lathe pod. Stock travels immediately and effectively for precision processing, helping to ensure quality for the finished products.

The company’s objectives are reduced leadtimes and faster-than-expected delivery, with the highest accuracy and cost effectiveness. With the partnerships C & A Tool has been able to establish, both with internal teams and vendor partners such as Hainbuch, these goals are consistently met or exceeded.

Related Content

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreCNC Turning Tips for HRSA Materials

Rough-turning, heat-resistant superalloys can be challenging. However, new carbide insert technology provides the capability to perform high-speed, high-feed roughing in a single pass.

Read MoreTool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreGerman Project Yields Three New Medical Machining Processes

Recent research has resulted in a new mix of high-speed turn whirl milling, polygon turning and rotational turning for manufacturing medical bone screws and out-of-round nails.

Read MoreRead Next

Selecting The Right Workholding Solution

These tips help solve turning, grinding and milling workholding problems, particularly for thin wall parts.

Read MoreWorkholding For Swiss Turning

In large part, because of the machine’s versatility, Swiss turning is increasing its penetration of the precision turned parts market. As more shops look to this technology, a look at workholding considerations is in order.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.png;maxWidth=300;quality=90)