Innovations in Five-Edged Parting and Grooving Inserts

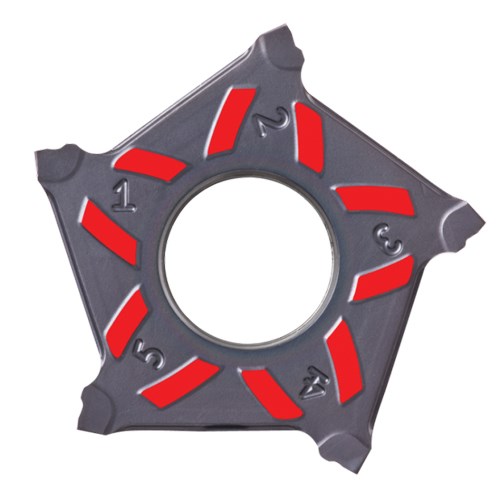

Here's an alternative to the standard circlip-type grooving system, offering five cutting edges with fast indexing from either side.

Part of the beauty of manufacturing and the science behind it will always be the way smart ideas are built upon. Further steps are constantly being taken to get more out of equipment and accessories to increase productivity or accomplish operations that previously were not practical. While 5-edged grooving and parting inserts have been in use for several years, there have been certain limitations that many shops have been counting on suppliers to work past.

Two new inserts from Iscar Metals Inc. are the company’s solution for the standard circlip-type grooving system, offering five cutting edges with fast indexing from either side. One size (Penta 24) is capable of parting off about a half inch diameter, and the larger (Penta 34) can part off a 20-mm diameter (about 3/4”). These inserts are designed for environments where catastrophic failure is common and where cost is a major concern. Limited depth-of-cut applications such as tubing or other thin-walled parts, as well as grooving operations, also fit well into their capabilities.

According to Matt Schmitz, Iscar’s national product manager for the Grip product line, the market has been calling for an economical solution for parting larger diameters—as much as 40 mm (more than an inch and a half). “To do that with the existing Penta design would be impossible,” says Mr. Schmitz. “The required carbide would be about five times the size of the existing Penta 34, which is already a large insert. We don’t have that capacity in pressing technology, and nobody would want to spend that much in raw materials.”

The company took the next steps in its insert design to achieve the 40-mm parting capacity with an insert that weighs less than the original Penta 34. “As with any product group, whether milling, drilling, threading, etc., the goal in achieving an economical insert is to get as many effective cutting edges onto the piece of carbide as possible,” says Mr. Schmitz. “Iscar designed the PentaIQGrip, a 5-edged insert with a greater diameter capacity that uses less raw material than the Penta34.”

Performance Enhancements

The insert is held by a dovetail clamping structure that ensures a face contact of the insert, which means that the insert is very rigid in the pocket and, therefore, capable of recessing and holding side forces. Other parting lines, such as Iscar’s original single-ended style SelfGrip, use a steel insert support with a mechanical or self-gripping mechanism to hold the insert in place. In these cases, straightness is largely dependent on the flex of the steel. However, with the PentaIQGrip line, the carbide insert is secured directly onto a large steel shank, reinforcing the rigidity. Now, the flex that occurs is limited by the rigidity of that carbide disk or wafer and, therefore, provides excellent straightness and surface finish for parting applications.

Although the insert may initially appear weak due to the reduced amount of material, it is proving to meet tough demands. Mr. Schmitz claims that he has performed tests that have exceeded the recommended parameters by four times, and because of the way the insert seats into the pocket, the rigidity holds up with a dead straight cut. Although he likes to push the limits, he has not yet broken an insert while making test cuts in Iscar’s test center.

Applying the Technology

A high production automotive account recently was using a 4-mm wide partoff. As much as the company wanted to move to 3 mm, tests with other products could never achieve the straightness that was required for the part. The PentaIQGrip, however, now allows this customer to do a 3-mm partoff with the straightness and finish necessary. The move has saved about $360,000 per year in material savings for that part.

The Swiss Market

Although Iscar has long supplied tools for Swiss machining, the company has not heavily marketed these products. However, the company is now beginning to address this initiative. The company’s SwissCut line offers a variety of inserts for turning, grooving, parting and threading, with integral holder shanks for 8, 10, 12 and 16 mm.

Although the PentaIQGrip product is currently only available in the 40-mm size, which is too large for the most common Swiss applications, products are currently in development to fit these machines.

“When I saw this product for the first time, Swiss was the first place I thought about applying it,” says Mr. Schmitz. “Our next offering will be the D32, in 2-mm width, for 32-mm Swiss machines. We will follow that up with a D22 so we will be able to fit the envelope of the most popular Swiss machines.”

Related Content

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreWhat Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreData Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More.png;maxWidth=970;quality=90)