Is Cleaning with Solvent More Beneficial than Aqueous Cleaning?

To understand solvent-based and aqueous cleaning methods, Venesia Hurtubise, technical chemist, MicroCare Corp., has compiled the following details about both processes.

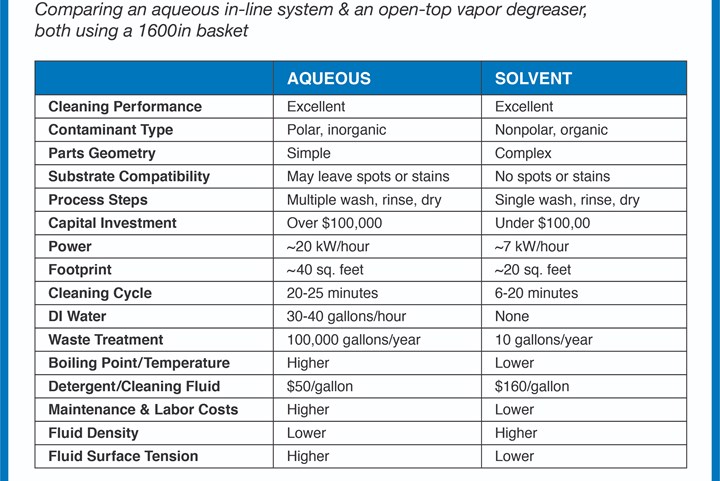

Aqueous cleaning has been used as a method for precision cleaning for a long time, but its efficiency and sustainability has been debated through the years compared with its solvent-based alternative. To understand both cleaning methods, Venesia Hurtubise, technical chemist, MicroCare Corp., has compiled the following details about both processes.

Aqueous Cleaning

Aqueous cleaning, or water-based cleaning, is particularly useful when combining the cleaning process with other procedures such as depositing rust preventers and brightener coatings. However, because the power to clean with water alone is weak, water is treated with a variety of compounds, including detergents or surfactants, builders, emulsifiers, saponifers, sequestering agents and chelating agents to strengthen its cleaning ability.

This method can be effective at cleaning metal parts. However, aqueous systems produce a waste stream that requires treatment before discharge. Wastewater must be filtered, distilled, deionized and osmosis prepped for disposal. The cleaning agent added to the water can be toxic and nonbiodegradable, making it problematic to dispose of.

There is also the added environmental impact of using large amounts of water and power during the cleaning process. Aqueous systems require high temperatures to be effective, using more power. Because the machines are generally bigger than solvent-based systems, they consume more energy. Also, because water in some parts of the world is a precious non-renewable resource, aqueous cleaning scores low for environmental sustainability.

Aqueous cleaning is also harder to dry completely. This is especially true for parts with blind holes and small gaps. Water can leave unwanted stains behind or lead to corrosion forming.

Solvent Cleaning

An alternative to aqueous cleaning is solvent-based cleaning using a vapor degreaser. Modern vapor degreasers use updated environmentally progressive solvent to deliver consistent and safe cleaning results.

These fluids are engineered with the correct characteristics such as high densities, low surface tensions and low viscosities to wet every surface. Solvents can penetrate the most complex of shapes to completely dissolve contaminants and remove even the most stubborn particulate. They are also compatible with a range of metals and plastics and clean a variety of soils with ease. These solvents are chemically and thermally stable, meaning they do not turn acidic with use, and are nonflammable for workplace safety.

Parts come out of a vapor degreaser clean, dry, spot-free and cool enough for immediate further processing or packaging.

Contaminants: Match and Remove

To remove contamination successfully, it is important to match the cleaning fluid (aqueous or solvent) to the contaminant itself. To do so, it is critical to understand whether the contaminant is a particulate, or a polar (inorganic) or non-polar (organic) soil.

Particulate that will not dissolve in water or solvent-based cleaning fluids include metal shavings, dust, surfactants, stearates and polishing pastes. The particulate cannot be dissolved or solubilized and instead is displaced from the part and washed away. The cleaning fluid gets under the particulate, dissipates the static holding it to the part and removes it from the surface. This cleaning method is used in both aqueous and solvent-based processes.

Inorganic contamination includes salts, soaps, emulsion residue and graphite. It also encompasses oxidation such as rust and tarnish, heat scale, smuts, and carbonaceous and metallic compounds. These soils are soluble in water; therefore, aqueous cleaners are effective at removing the particulate because like dissolves like. Water-based detergents and surfactants emulsify and encapsulate contaminants so they can be washed away.

Organic soils are non-polar halogenated, oxygenated and hydrocarbon soils. Examples include machining and stamping oils, grease, corrosion protection agents and esters and baked-on resins. Organic contamination can be dissolved and removed with specialty solvent-based cleaning fluids.

It is critical to choose a cleaning fluid according to the containment and ensure that it is chemically similar to the contaminant itself.

When educated on the contaminant to be cleaned and pros and cons of both aqueous and solvent-based cleaning, knowing which cleaning fluid and therefore, process, to use for an application should be clear.

To learn more about vapor degreasing, watch this video from MicroCare Corp. here.

Related Content

Versatile Sandblasting for Deburring Intricate Geometries

PMTS 2023: Comco’s MicroBlasting sandblasting systems can deburr, texture and clean small, intricate parts.

Read MoreSita’s CleanoSpector Measures Part Cleanliness

PMTS 2023: Handheld measuring device checks for cleanliness of parts to assure product quality as well as prior to follow-up processes.

Read MorePMTS 2023 Product Preview: Parts Cleaning

Learn about some of the latest parts cleaning solutions that will be on display at PMTS 2023.

Read MoreParts Cleaning Sector Shifts Energy Toward Regulatory Changes

With changes in EPA regulations regarding the use of some popular cleaning fluids, cleaning suppliers and end users are readjusting business strategies and/or cleaning processes to meet new requirements.

Read MoreRead Next

Selecting Solvents for Precision Cleaning

Stringent standards on precision cleaning ensure reliable and trouble-free performance in the final product.

Read MoreAqueous Cleaning Optimization

David Gotoff, product manager at Chemetall, explains how each area of an aqueous process must be optimized, including system design and mechanical action, chemistry selection, key performance indicators, soil management, maintenance, rust protection, rust preventive selection, water chemistry, and drying.

Read MoreTest to Find Answers to a Cleaning Solution Dilemma

Finding the best cleaning fluid for a specific application is possible by carrying out practical trials, backed by lab analyses.

Read More