Mist and Smoke Collectors for Metalworking Applications

While many companies are aware of the traditional problems associated with oil mist, few are aware that failure to adequately address mist and smoke issues often results in reduced productivity and increased machine downtime.

While many companies are aware of the traditional problems associated with oil mist (health and accident risks, cleaning and maintenance costs, and so on), few are aware that failure to adequately address mist and smoke issues often results in reduced productivity and increased machine downtime.

In addition to the obvious effects of oil mist, production is often reduced as a result of employees dialing back on feeds and speeds to minimize mist production. An often overlooked maintenance problem is the effect of oil mist on electrical contacts and electronic circuits.

To help in the battle against excessive smoke and mist and the related risks to personnel and productivity losses, Royal Products offers the Royal Filtermist mist and smoke collectors. Available in four sizes ranging from 275 to 1,200 cfm, these units are designed to offer the metalworking industry a low-cost, high-efficiency solution. They can be mounted in a variety of ways.

How it Works

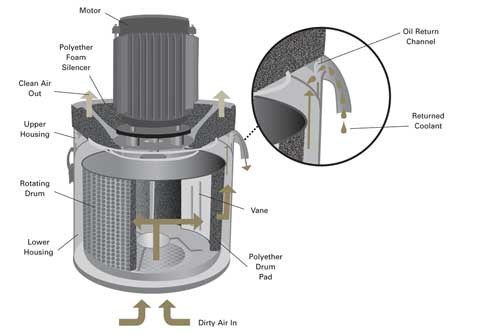

The Filtermist uses the principle of centrifugal impaction to eliminate mist. Operation is a fairly simple mechanical process—the unit has only three main components (drum, motor and housing). Maintenance requirements are minimal, but it should be noted that the drum pads are not filters. The porous pads are present to slow airflow through the unit, maximizing contact with the drum vanes for greatest overall impaction efficiency. Some customers have reported that they have gone as long as five year without needing to change these pads.

A three-phase motor rotates the internal drum at high speed, creating a vacuum that draws mist particles into the center of the drum. The mist particles then collide with the rotating drum’s vanes and are forced together with other particles, causing them to coalesce and form larger, droplet-sized particles.

As the particles grow into droplets, they pass through the perforations in the rotating drum and centrifugal force causes them to be thrown onto the inner wall of the housing. The particles are then forced, under pressure, up the walls of the housing to the oil return channel, where they are subsequently drained back to the machine’s coolant tank. Clean, oil-free air blows past the motor and is returned to the shop for re-use.

The units are able to maintain high efficiency because the process relies on the mechanical principle of centrifugal impaction and the rotational speed remains constant. For certain applications that produce smoke and/or very fine mist particles, an after filter may be required. This filter can be mounted to the top of the Filtermist unit by slipping it over the motor. It is secured in place with two toggle clips.

Latest Design

Filtermist mist and smoke collectors have been in use for about 30 years. While all designs have been based on centrifugal impaction, extensive computer-aided modeling and laboratory testing have led to the ninth generation model. The FX Series incorporates a number of design improvements aimed at providing improved effectiveness.

The FX carries a reduced weight for more flexibility in mounting the unit. The oil return channel has been enlarged to allow processing of a greater amount of liquid. Testing results have helped engineers optimize the gap between the drum and housing for maximum filtration efficiency.

Positioned near the bottom of the unit, at the intake, a conical air deflector accurately controls airflow within the unit. Air flow is automatically regulated as machine doors close to keep the correct negative pressure inside the enclosure. There is no need to adjust the drum speed.

The unit includes a heavy-duty, 3-phase motor that meets all federal, state and local electrical and safety codes. Dynamic balancing, uniform mass distribution, and neoprene isolators separating the motor/drum assembly from the housing assist in vibration control. The curved drum vanes are designed to improve airflow through the unit.

Cleaner Environment

Any form of pollution is potentially dangerous to employees, and oil mist creates slippery surfaces and increased fire risks. Installation of a mist collector can help reduce these hazards while saving on coolant costs, heating and cooling and cleaning and maintenance. The flexible, modular design of the Filtermist can be a simple step towards increased shopfloor productivity.

Read Next

Breathe Easier With Oil Smoke And Mist Filtration System

Removal of the smoke and mist created by machining oils results in a cleaner plant and a healthier working environment for employees.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.jpg;maxWidth=300;quality=90)