Pigging Out: High Feed Machining Techniques For Small Cutters

Small machining applications—those relying upon tool diameters smaller than 2. 0 mm—are continuing to grow based upon both consumer demand and developing machining technology. It’s apparent that the trend to produce ever-tinier electronic goods will continue (smaller cell phones, minute keyboards, plastic ear buds, and so on); all require small and precise mold insert creation.

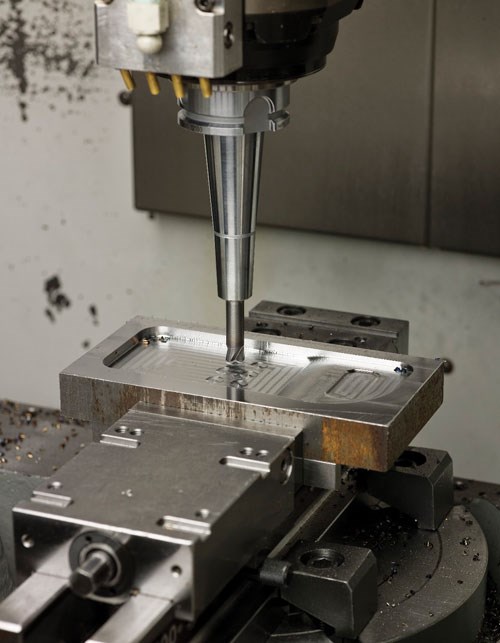

Small machining applications—those relying upon tool diameters smaller than 2.0 mm—are continuing to grow based upon both consumer demand and developing machining technology. It’s apparent that the trend to produce ever-tinier electronic goods will continue (smaller cell phones, minute keyboards, plastic ear buds, and so on); all require small and precise mold insert creation. With this smaller size demand, manufacturers are also clamoring for more speed, better finish and a higher degree of accuracy. Once an area best accomplished by the slower, yet reliable EDM process, we see the increasing move to metalcutting as machine and cutting tool technology continue to develop and meet these demands.

Even though the original billet of hardened tool steel that arrives on the production floor may be small, the material removal may be a large percentage of its entire size. It is common to remove 50 percent of material in these small mold applications. Our recommended technique for fast metal removal in small applications relies upon a high feed milling (HFM) strategy coupled with solid carbide end mills. Although it’s becoming common to see HFM applied to softer materials, it is still relatively new to the hardened steel applications (45–65 Rc). HFM uses a smaller depth of cut (no more than 10 percent of the micro tool diameters of 0.1 mm to 2.0 mm), faster feed per tooth (a factor of 5 times higher feed rate is common) and a surface feed rate of often 10 times above the norm. This approach reduces heat generation to extend tool life and provides a higher metal removal rate than normal—as much as 200 to 300 percent faster than traditional milling.

The reason for this is that the HFM method takes advantage of small setting angles. This produces minimal radial and maximal axial cutting forces. The cutting forces are directed at the machine spindle in the axial direction, which reduces the risk for vibrations and stabilizes machining. This, in turn, allows for the higher cutting parameters even when machining with a large overhang.

With the unique challenges presented by micro-machining, HFM presents some obvious benefits. Small, solid carbide end mills can quickly produce intricate shapes with tight tolerances and better surface finish. However, in order to reach into the small features, the length of the tool often has an extreme length-to-diameter ratio. For example, it could be possible to use a 2-mm diameter tool that is 30-mm projection length, an extreme 15-to-1 length-to-diameter ratio. Translate millimeters to inches and imagine trying a 2-inch tool at a 30-inch projection length. Couple this with the low tool stiffness because of small tool size and deflection can become a huge issue. The HFM methodology relieves this issue by reducing the radial forces.

Another HFM time-saver is the number of operations. Since high feed roughing with its small depths of cut generates a shape close to the final requested form, semi-finishing operations can often be eliminated, and NC programming is thus simplified. On top of this, the HFM process does not require increased rotational speed from the machine.

To accomplish an HFM strategy in small component machining, users need to evaluate the overall tool system. The first requirement is high-speed CNC machining capability and high-spindle accuracy with thermal stability against spindle growths. Without this, it will be difficult to machine precision components in a manner that is more efficient and accurate than EDM. Second, a CAM software program must be in place that can handle toolpath smoothing strategies such as corner rounding and helical cutting paths. Smooth tool paths enable a gentle slicing of the workpiece through light engagement conditions while helical cutter movements reduce the cutting impact, energy consumption and cutting forces.

Even though HFM helps to reduce vibrations and provide machine stabilization by directing the cutting forces at the machine spindle in the axial direction, toolholding in these small-component applications is critical. There are various toolholding options, but for exceptional rigidity and accuracy, a thermal tooling system offers the best precision available. Most tooling vendors, Seco included, offer complete shrink-fit systems for shrinking tool shanks into the toolholder. These systems offer superior runout control, especially critical for small-diameter cutters.

In terms of cutting tools, solid carbide is the best choice for quick metal removal in small applications. But, cutting tool geometry, coating and substrate all play a role. Each workpiece material requires a slightly different carbide tool composition in order to optimize the tool’s efficiency. In the Seco Jabro solid carbide line, application-specific tools such as the JM100 series are designed to machine hardened tool steels up to 55 Rc. To enhance hardness, these tools are produced from an ultra-fine carbide grain structure, which eliminates the need to machine workpieces prior to hardening (saving yet another step). These tools are coated with an aluminum titanium carbide nitride coating that is heat resistant and forms a layer of low friction aluminum oxide at working temperatures. This helps with chip evacuation and minimizes heat transfer from the chips back to the cutting tool. Additionally, these two-tooth end mills feature a 0-degree rake for strong cutting-edge presentation.

A small component application may appear more as “pigging out” versus “hogging out” the material in terms of cubic inches. But, when you look at the ratio of metal removal to original material size, it becomes obvious that metal removal speed and accuracy is critical to compete in the micro-machining field. A well thought out and executed high feed machining strategy can help significantly improve productivity by increasing feed rates, reducing operations and increasing tool life.

Related Content

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Read MoreShop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

Read MoreWhat Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreNew Cutting Tool Technology Discovered at Paul Horn Open House

During a tour of the company’s campus in Tubingen, Germany, I and more than 3,000+ others were introduced to a number of new advances the company has made in cutting tool technology particularly as it relates to the medical industry.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More