The precision machining industry faces a relentless challenge to constantly find new ways of increasing productivity, while ensuring the continued production of high quality components. Highly efficient tooling and machining methods involve raising feed rates, boosting cutting speeds and increasing the depth of cuts – all while maintaining the all-important quality.

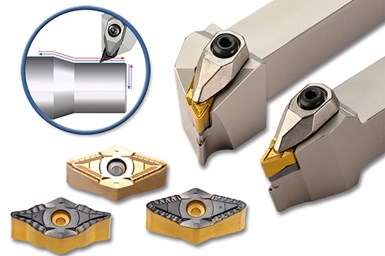

Cutting tool manufacturers are rising to this challenge. This month, our Technology Showcase is highlighting some of the product information that PM received from supplier companies. For April, we focused on cutting tools, including standard coated-carbide ISO-P steel insert grades for common steel turning operations; drilling units customized for particular operations; IG6 and SG3 coatings for cartridge tooling systems; and more as described below.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s March Technology Review.

Click on each link below to read the full product post:

Related Content

New Cutting Tool Technology Discovered at Paul Horn Open House

During a tour of the company’s campus in Tubingen, Germany, I and more than 3,000+ others were introduced to a number of new advances the company has made in cutting tool technology particularly as it relates to the medical industry.

Read MoreData Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

Read MoreMicromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

Read MoreMaking Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreRead Next

Precision Machining Technology Review February 2022: Automation & Robots

Production Machining’s automation and robotics showcase includes Mitsubishi Electric, Carr Lane, Made4CNC, FANUC, United Grinding and Comau.

Read MorePrecision Machining Technology Review January 2022: Toolholding

Production Machining’s toolholding showcase includes Schwanog, Somma Tool, Big Kaiser (Big Daishowa), Allied Machine & Engineering, Kaiser Tool Co. and Exsys Automation.

Read MorePrecision Machining Technology Review March 2022: Software

Production Machining’s Software showcase includes Siemens Digital Industries, Open Mind Technologies, iTSpeeX, FANUC, Paperless Parts, Wintriss Controls Group and TDM Systems.

Read More